Why are aluminium alloys so widely used in production today? The reasons for this are numerous and we explain the reasons for their popularity in 4 ways next.

Aluminium alloys can be formed into a variety of alloys. Aluminium can be combined with copper, manganese, magnesium, silicon, zinc, lithium, nickel, iron and silver to form alloys with different unique properties to meet the needs of different projects and components. There are 670 deformed aluminium alloys currently in common use (active alloys) and non-inactive alloys registered with the Alcoa Corporation, forming 8 series ranging from the industrial pure aluminium 1XXX series to the 8XXX series. The strength properties of many aluminium alloys can be further improved by heat treatment. The specific strength (strength/density ratio) of some aluminium alloys can now be comparable to that of high quality alloy steel.

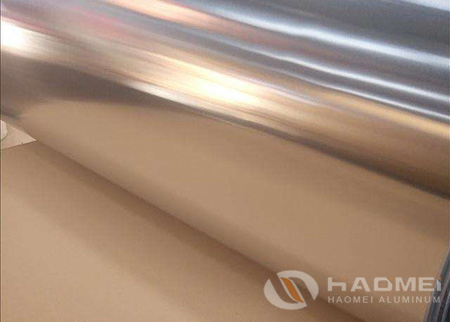

Aluminium alloys are highly light reflective. The surface of polished aluminium reflects more than 90% of light at wavelengths of 0.9 to 12.0 μm and less than 70% of light at wavelengths of less than 0.2 μm. The reflectivity of aluminium to radio waves and visible light waves decreases sharply with the increase in surface roughness. As aluminium is highly reflective of visible light, it is widely used in searchlights, daytime lamps and other applications.

The nuclear irradiation resistance of aluminium alloys. Aluminium has a small thermal neutron absorption cross section of about 0.23 x 105pa and is used as a nuclear fuel process tube (aluminium-magnesium-silicon alloy) in nuclear reactors, which is particularly suitable for use in thermal neutron nuclear reactors.

Aluminium resources are abundant. Aluminium is the most abundant metallic element on the surface of the Earth and the Moon, and is inexhaustible for the world - unlike iron, and unlike copper, which faces the daunting challenge of increasing resource depletion. Of course, despite the above-mentioned advantages, aluminium has some inherent disadvantages and shortcomings which can be improved and compensated for by alloying and processing, and these need not worry the purchaser.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog