The importance of aluminium bodies for cars and BIW

Generally speaking, the lighter the car the faster it picks up and the sportier it feels, while cornering roll is reduced, all while power remains the same. A lightweight all-alloy body squeezes out the ultimate in power and handling performance. And the lighter the car and BIW is, the safer it is at the same strength. The heavier the body, the greater the inertia, the greater the impact force borne in the event of an accident, and the more serious the consequences of the accident.

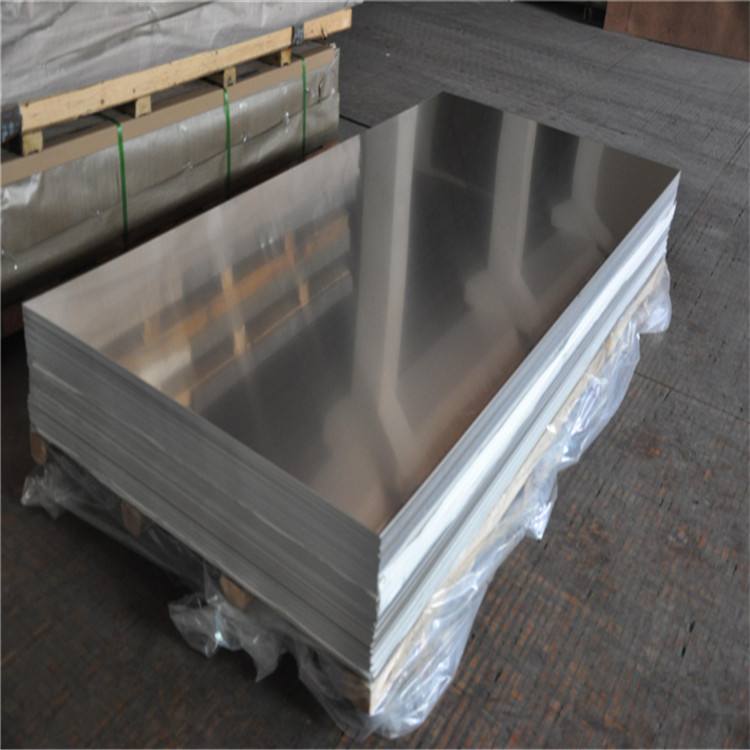

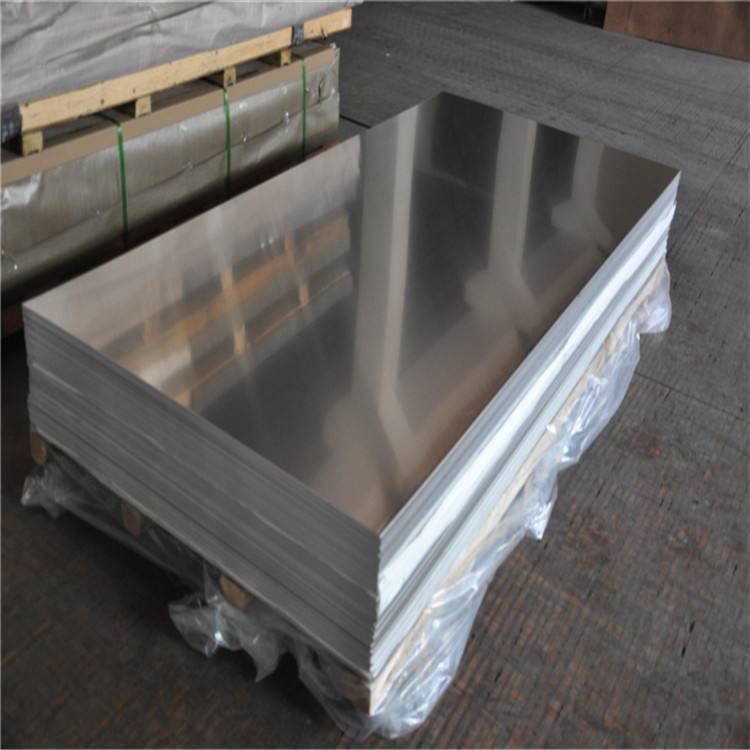

I. Application of aluminium alloy bodywork and BIW

One of the trends in car manufacturing now is to use aluminium and other materials to manufacture large body parts to reduce the weight of the vehicle, such as the engine hood, roof and door panels. Vehicles such as the Audi A6, Renault Laguna ii, Peugeot 307 and Opel Vettel C have aluminium bonnets and the Renault Laguna ii uses aluminium for the bonnet, roof and door panels. There are many manufacturers who have introduced aluminium into the production of structural body parts, or even made the entire body entirely out of aluminium, in vehicles such as the Audi A2, A8, Jaguar XJ and others such as the BMW 5 series, which use aluminium for the front structural and exterior panels.

Second, the advantages of aluminium alloy bodywork and BIW

1、The specific gravity of aluminium is about one third of that of steel. The application of aluminium in the manufacture of bodywork can reduce the weight of the vehicle by 20-30%, which can improve the handling of the vehicle.

2. The advantage of aluminium alloy bodywork is not only in reducing the weight of the bodywork, but also in reducing fuel consumption. This means a saving of 0.5 litres of fuel per 100 kilometres.

3. Another advantage of the aluminium body is its environmental performance. As already mentioned, this can reduce fuel consumption and reduce pollution emissions during the production process. It is also because 99% of the aluminium can be recycled, which to a certain extent compensates for the high consumption costs incurred in the smelting of aluminium from aluminium ore.

Of course, aluminium bodies and BIW also have a number of disadvantages, such as the high cost of construction. One is that aluminium itself is more expensive, with the price of some aluminium alloys even exceeding that of gold, and the other is that the production process is more complicated and has more technical difficulties, as mentioned earlier. For this reason, all-aluminium bodies for cars are now basically used in luxury high-end vehicles.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog