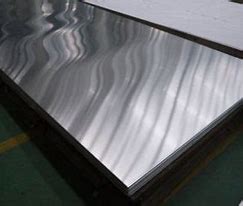

Aluminum strips are widely used in various industries due to their lightweight, corrosion resistance, and high strength-to-weight ratio. The properties of aluminum strips make them an excellent material for use in applications such as construction, transportation, and electronics. To meet the demands of these industries, several manufacturing methods have been developed to produce 1-inch aluminum strips.

The four most common manufacturing methods for producing 1-inch aluminum strips are hot rolling, cold rolling, extrusion, and drawing.

Hot rolling is the most common method for producing aluminum strips. In this process, the aluminum billet is heated to a high temperature and then passed through a series of rollers to reduce its thickness. The high temperature makes the aluminum more malleable, allowing it to be formed into thinner and longer strips. Hot rolling is a fast and efficient method that offers high production rates and excellent surface finish.

Cold rolling is used to produce aluminum strips with tighter tolerances and improved mechanical properties. In this process, the aluminum billet is cooled and then passed through a series of rollers to reduce its thickness. The cooling process makes the aluminum more brittle, which means that it can be formed into thinner strips with greater precision. Cold rolling is a slower process than hot rolling, but it produces aluminum strips with a higher tensile strength and a more consistent thickness.

Extrusion is a process that involves forcing the aluminum billet through a die to produce a continuous profile. Extruded aluminum strips are known for their excellent surface finish and dimensional stability. This process is used to produce complex shapes and profiles that are difficult to achieve using other methods. Extruded aluminum strips are used in applications such as automotive trim, building facades, and window frames.

Drawing is a process that involves pulling the aluminum billet through a series of dies to reduce its diameter. This process is used to produce aluminum strips with very tight tolerances and improved mechanical properties. The drawing process can produce aluminum strips with a high degree of uniformity, making them suitable for use in applications such as electrical conductors and heat exchangers.

The choice of manufacturing method depends on the specific requirements of the application, including the desired mechanical properties, surface finish, and dimensional accuracy of the final product. Each method has its advantages and disadvantages, and the selection of the appropriate method is critical to ensure that the final product meets the required specifications.

In conclusion, the manufacturing of 1-inch aluminum strips is a critical process that requires careful consideration of the specific requirements of the application. By understanding the advantages and disadvantages of each manufacturing method, manufacturers can select the appropriate method to produce aluminum strips that meet the required specifications.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog