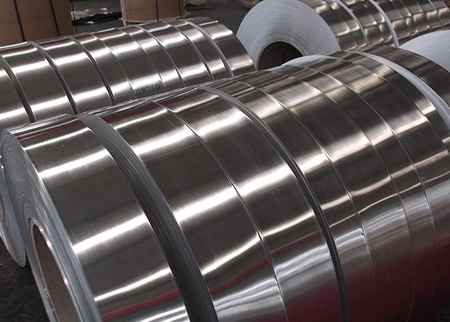

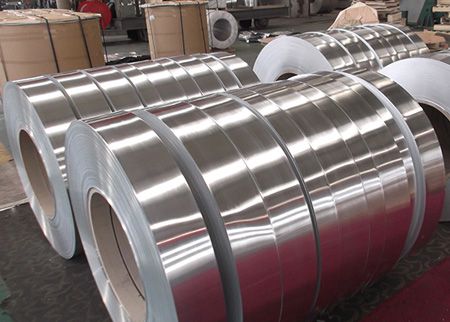

Aluminum strips are a highly versatile material used in a wide range of industries, such as construction, automotive, and aerospace. These strips are valued for their lightweight, corrosion-resistant properties, and high strength-to-weight ratio. The manufacturing process for aluminum strips is a complex one that involves several steps, each of which plays a critical role in producing a high-quality product.

The first step in manufacturing aluminum strips is casting. This process involves melting raw aluminum and pouring it into a mold to form a slab. The slab is then allowed to cool and harden, after which it is cut into smaller pieces called billets. The casting process is crucial because it determines the quality of the final product. If the casting is not done correctly, it can result in defects such as cracks or voids that could weaken the aluminum strips.

The next step is rolling. The billets are heated and passed through a series of rollers to reduce their thickness. The rollers apply pressure to the billets, causing them to elongate and narrow into long sheets. This process is repeated several times until the desired thickness is achieved. Rolling is an essential step in the manufacturing process because it determines the final dimensions and properties of the aluminum strips.

After rolling, the aluminum strips are annealed to enhance their properties. Annealing involves heating the strips to a specific temperature and then allowing them to cool slowly. This process helps to reduce the internal stresses in the strips and improve their ductility. Annealing is a critical step in the process because it determines the final strength and durability of the aluminum strips.

Once annealing is complete, the aluminum strips are ready for finishing. Finishing involves cutting the strips to the desired length and width and applying any necessary surface treatments, such as coatings or polishing. This step is crucial because it determines the final appearance and surface quality of the aluminum strips.

In conclusion, the manufacturing process for aluminum strips is a complex one that involves several critical steps. By following the casting, rolling, annealing, and finishing steps, manufacturers can produce high-quality aluminum strips that meet the needs of various industries. The properties of aluminum strips make them an excellent choice for many applications, and the manufacturing process ensures that they are produced to the highest standards of quality and reliability.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog