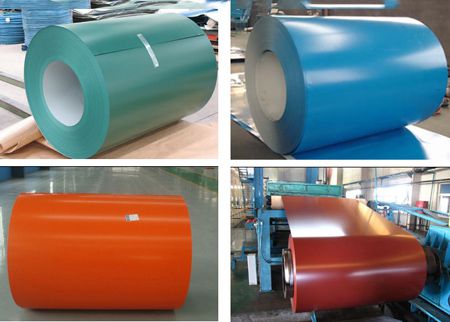

PVDF color-coated aluminum coil is widely used in the construction industry due to its excellent weather resistance, corrosion resistance, and long-lasting color. The roller coating process is an important step in the production of PVDF color-coated aluminum coil. Here are the steps involved in the roller coating process:

Cleaning the Aluminum Coil: The first step in the roller coating process is to clean the aluminum coil thoroughly. This is done to remove any dirt, dust, or other contaminants that may be present on the surface of the coil.

Pre-Treatment: After cleaning, the aluminum coil is treated with a chemical solution to enhance its surface properties. This process is called pre-treatment and it helps to improve the adhesion between the aluminum coil and the coating material.

Coating Application: Once the pre-treatment process is complete, the PVDF coating is applied to the surface of the aluminum coil using a roller coating process. The coating is applied in a uniform layer to ensure that the entire surface of the coil is covered.

Curing: After the coating is applied, the aluminum coil is subjected to a curing process. This process involves heating the coil to a specific temperature for a defined period of time to ensure that the coating material is fully cured. This helps to improve the durability and weather resistance of the coating.

Inspection: Once the curing process is complete, the coated aluminum coil is inspected to ensure that it meets the required quality standards. This includes checking the thickness, color, and adhesion of the coating.

Packaging: Finally, the PVDF color-coated aluminum coil is packaged and prepared for shipment to the customer.

By following these steps, manufacturers can produce high-quality PVDF color-coated aluminum coils that are durable, weather-resistant, and long-lasting.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog