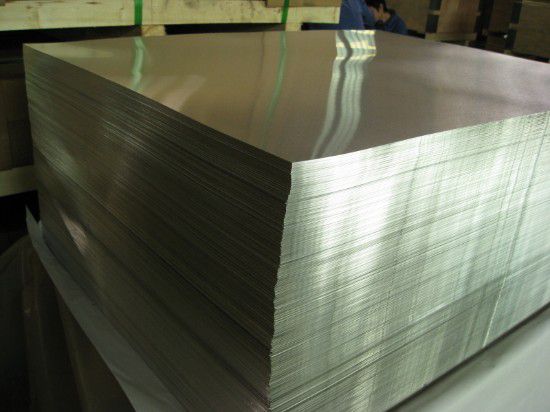

When it comes to achieving highly precise aluminum sheets, there are several methods that can be used. However, the most cost-effective way to achieve precision in aluminum sheet manufacturing is by using the process of cold rolling.

Cold rolling is a process that involves passing the aluminum sheets through a series of rollers, which compress and reshape the metal. This process not only achieves precision in the shape of the aluminum sheet but also improves its strength and durability. The process is carried out in a controlled environment, which means that the aluminum sheet is not exposed to high temperatures or extreme stress, ensuring that the final product is of high quality.

Another advantage of cold rolling is that it can be used to produce large quantities of aluminum sheets quickly and efficiently. The process is highly automated, which means that it requires minimal labor and reduces the overall production cost. This makes it an attractive option for businesses that require large quantities of aluminum sheets in a short amount of time.

In addition to cold rolling, other methods that can be used to achieve precision in aluminum sheets include hot rolling, extrusion, and forging. However, these methods are generally more expensive and may not be as cost-effective as cold rolling. Hot rolling, for example, involves exposing the aluminum sheet to high temperatures, which can cause the metal to become less durable.

Extrusion is another method that involves forcing the aluminum sheet through a die to achieve the desired shape. While this method can be effective in achieving precise shapes, it is generally more expensive than cold rolling.

Forging is a process that involves hammering the aluminum sheet to shape it. While this method can be effective in achieving precise shapes, it is generally more time-consuming and labor-intensive than cold rolling.

In conclusion, if you are looking for a cost-effective way to achieve precision in aluminum sheet manufacturing, cold rolling is the way to go. It is a highly efficient and automated process that produces high-quality aluminum sheets with precision in shape, strength, and durability. It is an ideal option for businesses that require large quantities of aluminum sheets in a short amount of time, and it is also a more environmentally-friendly option than other methods.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog