PRODUCTS

Color coated aluminum coil is a type of aluminum coil for sale that is painted PVFD from PPG or Valsper, which can not only color and beautify the surface of color coated aluminum coils, but also protect the inner material various among 1100, 3003, 3004, 3105, 5006, 5052, 8011, etc.

Online consultation

Online consultation

Project Introduction

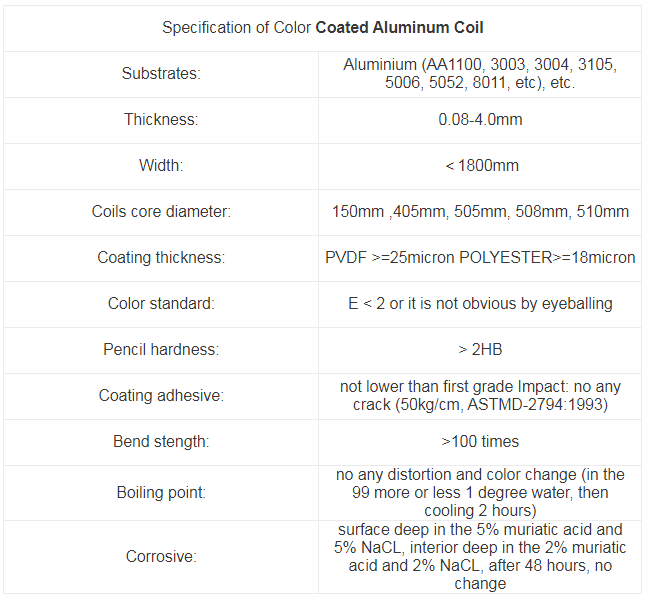

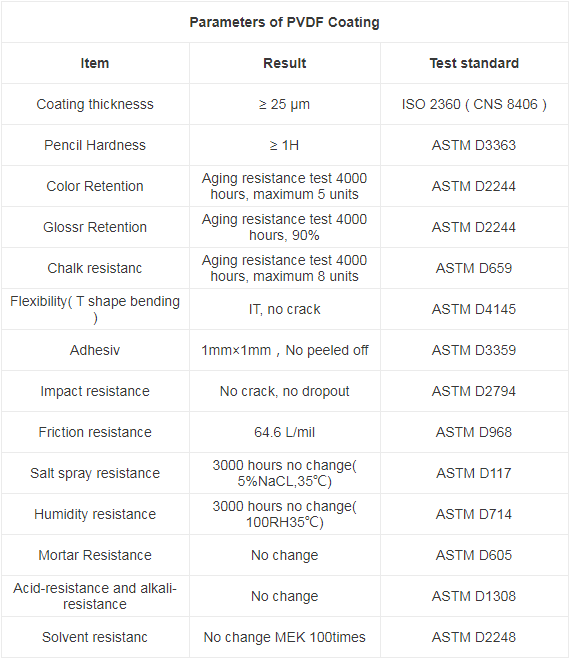

Color coated aluminum coil is a type of aluminum coil for sale that is painted PVFD from PPG or Valsper, which can not only color and beautify the surface of color coated aluminum coils, but also protect the inner material various among 1050, 1060, 1100, 3003, 3004, 3105, 5006, 5052, 5083, 5754, 8011, etc. And here are the parameters of color coated aluminum coils.

The color-coated aluminum coil is a composite material formed by coating one or more layers of organic coatings on the surface of the aluminum substrate after passing through the color coating unit and baking and curing. Color coated aluminum coil production process includes aluminum substrate degreasing, chemical pretreatment and coating process.

Haomei accepts all kinds of customization in color, material, size,etc. as long as you specify.

Overall, color coated aluminum products are practical, decorative, easy to process and durable. Color coated aluminum coil has the advantages of both aluminum coil and organic material. It not only has the advantages of high mechanical strength, good toughness, and easy processing and forming ability, but also has beautiful color, decorative ablity and corrosion resistance of organic polymer coating material. It can be easily processed - and you can produce it through punching, bending, deep drawing, welding, etc. Also, the surface layer can be guaranteed not to fade for at least 30 years after special treatment such as spraying. At the same time, it has low density, high hardness, and the weight per unit volume is the lightest among metal materials.

Overall, color coated aluminum is used in architectural decoration, food packaging, electronic appliances, printing, transportation and other fields:

1) Building decoration field: manufacturing roof panels, roof panels, curtain wall panels, interior wall decorative panels, ceiling panels, honeycomb panels, thermal insulation panels, rolling shutters, shutters, etc.

2) Food packaging field: manufacturing non-pressure food cans, pressure food cans, can lids, bottle caps, box lids, pull rings, food boxes, various food packaging sealed bags, etc.

3) Electrical and electronic fields: manufacture of air conditioner panels, washing machine panels, refrigerator panels, cabinet panels, and casings of various digital electronic products.

4) Printing aluminum: manufacture PS, CTP, UV-CTP printing materials.

5) Transportation field: manufacture box truck shells and inner walls, car body panels, train compartment panels, ship interior panels, traffic facility signs, advertising display panels, luggage.

Return

Return