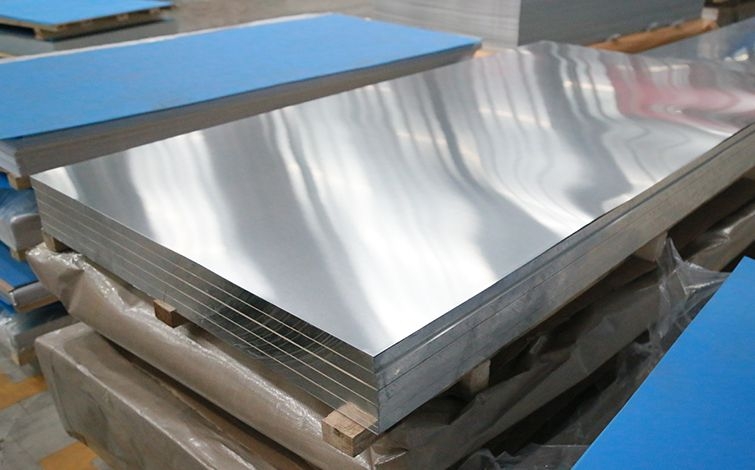

Production and processing of aluminium surface drawing

Aluminium alloy surface drawing can be made according to the decorative needs, such as straight pattern, messy pattern, thread, corrugation and rotary pattern.

Straight wire drawing refers to the processing of straight lines on the surface of aluminium alloys by means of mechanical abrasion. It has the dual function of brushing away the scratches on the surface of the aluminium alloy and decorating the surface of the aluminium sheet. There are two types of straight wire drawing: continuous and interrupted. The continuous wire pattern can be obtained by continuous horizontal linear abrasion on the surface of the aluminium plate with a cleaning cloth or stainless steel brush (e.g. in the condition of having a *now device for manual technical grinding or using a planer to hold the steel wire brush on the aluminium plate). Changing the diameter of the wire of the stainless steel brushes, different thicknesses of grain can be obtained. The interrupted wire pattern is generally produced by processing on a brushing machine or rubbing machine. The principle of production: two groups of differential wheels rotating in the same direction are used, the upper group is a fast rotating grinding roller and the lower group is a slow rotating rubber roller, the aluminium or aluminium alloy plate passes through the two groups of rollers and is brushed with a fine intermittent straight pattern.

The brushing of the aluminium or aluminium alloy plate is done at high speed with a brass wire, which moves the plate backwards and forwards, and gives it an irregular, matt pattern with no visible pattern. This type of processing is more demanding on the surface of the aluminium or aluminium alloy sheet.

The corrugation is generally produced on a brushing or rubbing machine. Using the axial movement of the upper set of grinding rollers, the surface of the aluminium alloy is brushed to produce a wavy pattern.

The rotary pattern, also known as rotary polishing, is obtained by using a cylindrical felt or stone nylon wheel mounted on a drill press and using paraffin and polishing paste to rotate and polish the surface of aluminium or aluminium alloy plates. It is mostly used for the decorative finishing of round signs and small decorative dials.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog