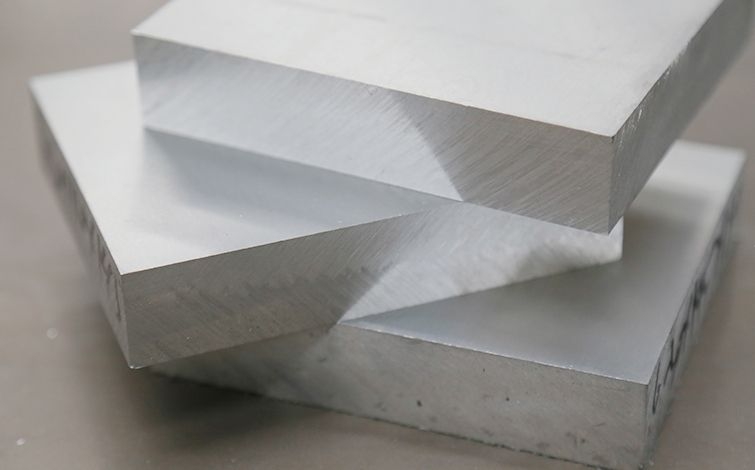

Aluminium plate drawing

The thread is made by using a small motor with a round felt on the shaft, fixed to the table at an angle of about 60 degrees to the edge of the table, and a dragging plate with a fixed aluminium press tea, to which a strip of polyester film with straight edges is attached to limit the thread bidding. Using the rotation of the felt and the straight movement of the dragging board, a thread pattern is created on the surface of the aluminium plate with a uniform width.

To be formed before bending etc., the plate is usually drawn. In fact, the surface treatment of the substrate has high requirements for the pre-treatment, otherwise the surface treatment but back to amplify the defects of the substrate

Surface drawing of plastic parts is generally done by hot stamping, in which the material on the hot stamping film is transferred to the plastic surface under the action of high temperature and pressure of the hot stamping machine. Different hot stamping films are used to obtain different glossy and coarse grain effects, and this process is used a lot on video disc player panels. Now in the audio-visual products with a lot of magic mirror decorative pieces, is in the PMMA plate stamping reflective film (also useful for electroplating) aluminum surface treatment in addition to brushed, but also commonly used sandblasting process, the same can play a role in covering scratches and beautifying the appearance of another "hot stamping" process (aluminum transfer), can be in the The surface of plastic parts can also be made to resemble this effect.

The hot stamping plate, that is, the pressure head part of the material selection, to red copper material for the best, because the red copper heat dissipation, heat transfer is relatively good, in the metal belongs to the neutral material, neither too soft nor too hard, not only easy to process, there is a certain flexibility, durability is very good; but the actual use, many manufacturers to reduce the cost of materials, the choice is more aluminum alloy printing plate, so in the hot plate production costs can save some, but Because the aluminum is too soft, poor service life, if the batch is very large, with a period of time also have to re-plate, plate fee is not cheap, so should be a comprehensive consideration of material selection issues.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog