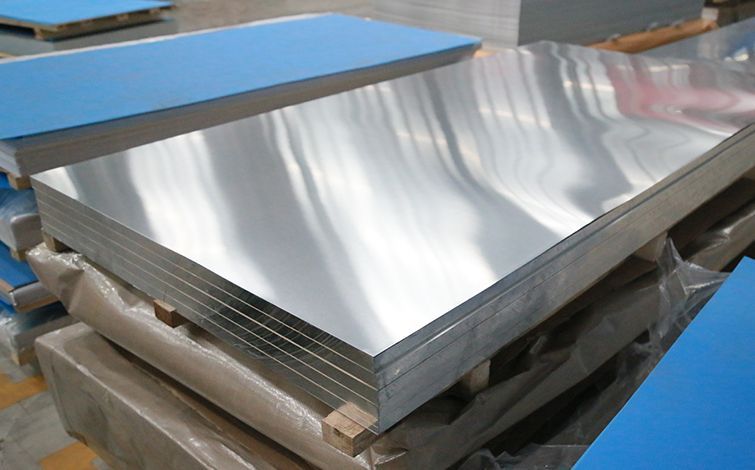

Today we are going to introduce the surface defects caused by aluminium finishing on aluminum sheets for sale, which we Haomei are always avoiding in production. The surface quality of aluminum alloy plates is strictly required, and defects such as minor scratches or scratches are easily detected. Therefore, the requirements, improvement and management of the surface quality of aluminum plate products are one of the most important tasks in production operations. What problems will generally occur on the surface of the aluminum plate? Let Haomei Aluminium take you to understand it!

First of all, the first problem with the surface of the aluminum alloy plates is the shear wave. Transverse wave is defined as a deformation crease created after a plate is bent. It is characterized by a crease that has been pressed by the pressure of the fold, and the wrinkle is at an angle with the rolling direction. At the same time, the folding place has a bright pattern. Its main cause is the unbalanced force of the sheet flap, handling or palletizing; The roll type of the calender is improper, and the plate is unevenly deformed; The wave of the plate before calendering is too large, and the straightening process is large and fast; Straightening and calendering when feeding is not correct; When cold rolling, the thickness of the strip is uneven and the aluminum alloy plate shape is poor.

The second problem with the surface of the aluminum alloy plates is the crease and compression fold. It refers to the part of the strip that has been rolled or sheared and the edges of the strip are cocked. The main reason for it is that the shear edge is not adjusted properly when shearing.

The third problem with the surface of the aluminum alloy plate is warp, which refers to the formation of regular light and dark stripes on the surface of the stretch plate at an angle of about 45° to 60° in the direction of the stretch. The main reason for it is that the amount of stretching is too large when pre-stretching.

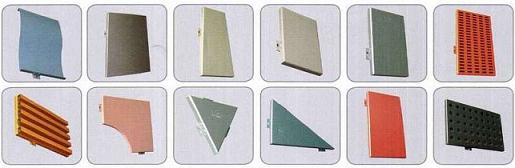

If you have other questions when choosing aluminum, you can consult us Haomei. Our standing stock is large, varied, full of specifications, products of aluminum sheets cover 1 to 8 series of multiple grades and specifications. Our quality is guaranteed and the supply is timely.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog