The 7 series aluminum-zinc-magnesium alloy is the first place in the superduraluminium alloy series. It was used to manufacture airplanes, aviation vehicles. If you need to buy 7 series aluminum alloy, please contact us Haomei Aluminum!

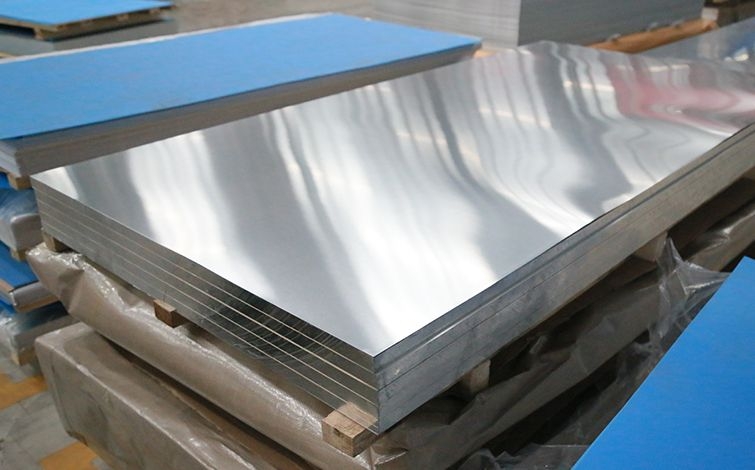

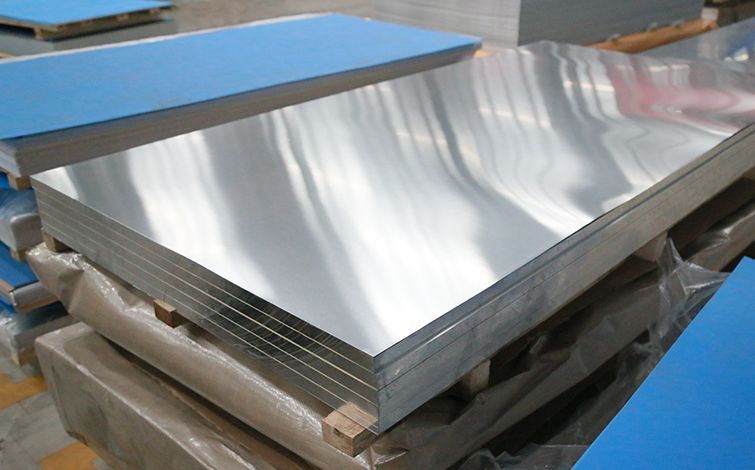

First of all, let's take a look at the characteristics of the 7 series aluminum-zinc-magnesium alloy. 7 series aluminum alloy, as a super-duraluminium alloy series, its material contains a large number of other metal elements, and the main alloying elements are zinc, magnesium, copper. The representative grades of 7 series aluminum alloys commonly on the market are 7050 and 7075. Their heat treatment effect is particularly good, is a super strong deformed aluminum alloy plate. After solid melting, the 7 series aluminum alloy has good plasticity and has good mechanical properties, wear resistance and fatigue resistance. However, they also have disadvantages: poor welding performance, tendency to crack stress corrosion, and need to be treated with aluminum or other protection.

Next, let's take a look at the common 7 series aluminum-zinc-magnesium alloy types on the market and their uses!

7075 : Used for aircraft parts, gears and shafts, instrument shafts and gears, mold manufacturing turbines, keys, aircraft, aviation and defense and other high-stress structural parts that require high strength and strong corrosion resistance. We manufacture 7075 aluminum alloy and 7075 aluminum plate. If you need, you can contact us by email!

7005: Extruded materials for the manufacture of welded structures with both high strength and high fracture toughness, such as trusses, members, containers for transportation vehicles; Large heat exchangers, as well as parts that cannot be solidified after welding; It can also be used to manufacture sports equipment such as tennis rackets and softball bats

7039 : Refrigeration vessels, cryogenic equipment and storage boxes, fire pressure equipment, military equipment, armor plates, missile devices

7050 : Medium and thick plates, extruded parts, free forgings and die forgings for aircraft structural parts. The requirements for the manufacture of such parts for alloys are: high resistance to spalling corrosion, stress corrosion cracking ability, fracture toughness and fatigue resistance

7A04: Aircraft skins, screws, and force components such as girder trusses, compartments, wing ribs, landing gear, etc.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog