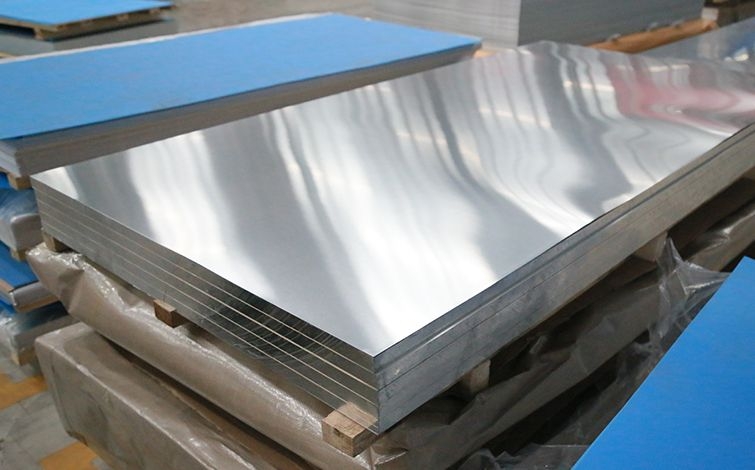

Aluminium foil is a versatile material that is widely used in various applications such as packaging, insulation, and cooking. It is a thin sheet of aluminum that is made by rolling and compressing aluminum metal. It has numerous advantages, including being lightweight, flexible, and easy to handle. In this article, we will discuss in detail the regular thickness range of aluminum foil rolls.

The thickness of aluminum foil rolls can vary depending on their intended use. Generally, the thickness of aluminum foil ranges from 0.00017 to 0.2 inches. However, the thickness can also be measured in microns, with the standard range being 6-40 microns. For household use, the thickness of aluminum foil is typically between 0.0004 and 0.0007 inches or 10-18 microns. These are commonly used for wrapping food items, covering dishes, and lining baking sheets.

In industrial settings, thicker aluminum foil is used for insulation, packaging, and other applications. Foil with a thickness of up to 0.03 inches or 800 microns is used for insulation, while thicker foil, up to 0.2 inches or 5000 microns, is used for packaging and other applications. Thicker aluminum foil provides better durability and strength, making it ideal for industrial use.

The thickness of aluminum foil also affects its performance in terms of heat resistance and conductivity. Thinner foils are better suited for low-temperature applications, while thicker foil is better for high-temperature applications. The thickness of aluminum foil also affects its barrier properties, such as moisture and gas resistance.

In conclusion, the regular thickness range of aluminum foil rolls varies depending on their intended use. For household use, the thickness is typically between 0.0004 and 0.0007 inches or 10-18 microns, while in industrial settings, thicker foil is used for insulation and packaging. It is important to choose the right thickness for the intended use to ensure that the foil performs its intended function effectively. The thickness of aluminum foil also affects its performance in terms of heat resistance, conductivity, and barrier properties. Therefore, it is essential to consider these factors when selecting the appropriate thickness for a specific application.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog