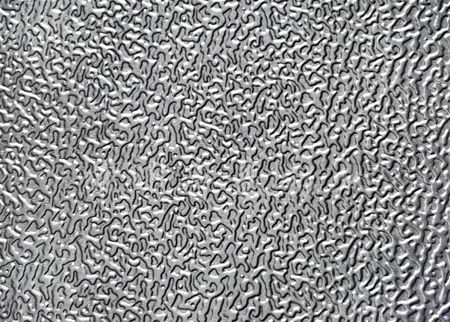

Embossed aluminum plate how to remove oxidation

Embossed aluminum sheet manufacturers Haomei aluminum for everyone to introduce the following measures to prevent oxidation:

1. Degreasing treatment, with degreasing cotton wet solvent wipe, remove the oil, and then wipe with a clean cotton cloth several times can be. Commonly used solvents include trichloroethylene, ethyl acetate, acetone, butanone and petrol.

2. After degreasing, chemical treatment in the following solution: ammonium hydrogen fluoride 3-3.5, chromium oxide 20-26, sodium phosphate 2-2.5, concentrated sulphuric acid 50-60, boric acid 0.4-0.6, water 1000 at 25-40°C for 4.5-6min, i.e. water washing and drying. This method of gluing strength is higher, after treatment within 4h gluing, suitable for epoxy and epoxy-butyronitrile gluing.

3. After degreasing, the surface is anodised in the following solution: 22g/l concentrated sulphuric acid at a DC strength of 1-1.5 A/dm2 for 10-15min, then in a saturated potassium dichromate solution at 95-100°C for 5-20min, followed by washing and drying. The treated metal surface is highly reactive and is more susceptible to recontamination by dust, moisture etc. The treated metal surface should therefore be glued as quickly as possible.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog