Why aluminium oxide films protect aluminium from oxidation and corrosion

When aluminium is oxidised, a film of aluminium oxide poles forms on its surface acting like a liquid, protecting it from oxidation by filling the gaps that form and preventing oxygen from entering.

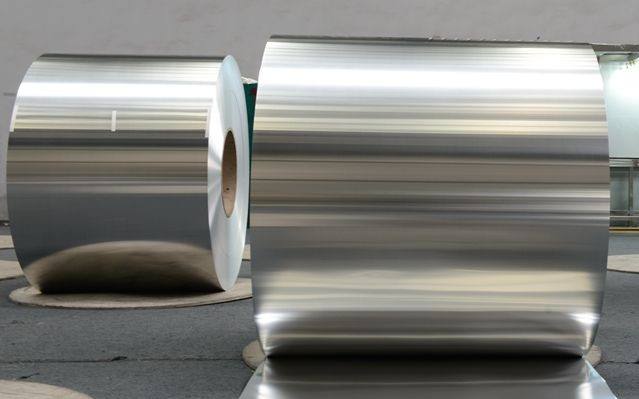

The metal may look hard, but given enough time, even pure air can remove them. Oxygen reacts with aluminium alloys to form rusty metal oxides, but it has now been shown that metal oxides may be able to save the life of aluminium alloys. It has been found that aluminium can be protected from further oxidation by a thin film of aluminium oxide, which acts like a liquid and fills any gaps that form as it flows.

If metal oxides such as rust or corrosion are allowed to build up, they can eat away at the metal and eventually cause it to break down. However, not all metal oxides are so destructive. Three particular oxides: aluminium oxide, chromium oxide and silicon dioxide, can actually serve to protect metals from further corrosion.

Under particularly stressful conditions, such as inside a reactor, corrosion can occur very quickly. The researchers tested how well the coatings of these special oxides protected the metals beneath them when exposed to oxygen and placed under mechanical stress.

Comparisons were made over time, as the aluminium oxide layer deformed and elongated to protect the aluminium from the effects of oxygen

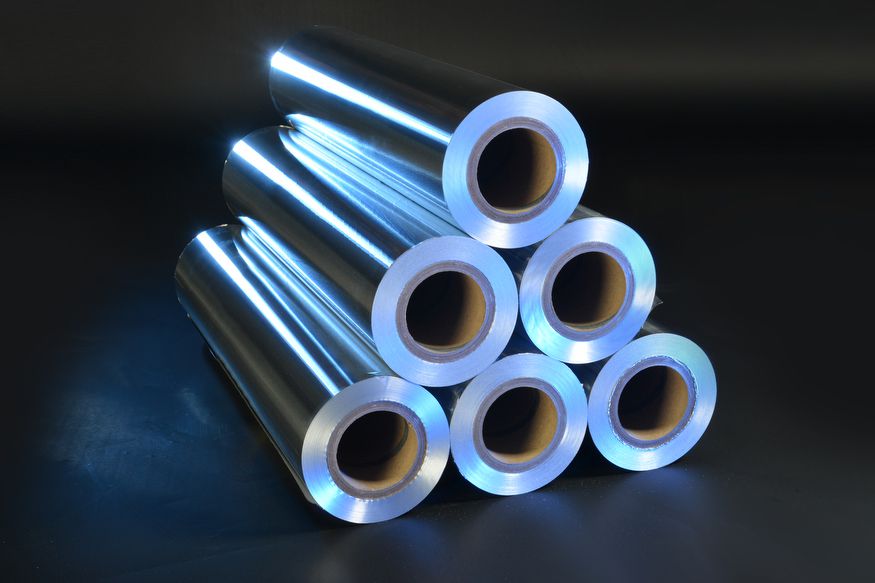

Aluminium oxide films perform well, and although aluminium oxide is a solid, it behaves like a liquid when coated in very thin layers of about two to three nanometres. As the aluminium stretches, the oxide layer elongates and keeps the metal covered, thus preventing oxygen from entering.

The researchers were able to demonstrate this phenomenon at room temperature, stretching aluminium twice its original length without breaking. Aluminium oxide is usually brittle, but the thin layer was found to deform almost as well as normal aluminium.

This self-healing coating could be used in highly stressful situations such as in fuel cells or nuclear power plant reactors. Because it is so reactive, the researchers say it may be particularly suitable for containing tiny molecules, such as hydrogen, which can pass through most other materials.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog