Lithium batteries are widely utilized in a diverse range of devices, including laptops, mobile phones, and electric vehicles. In fact, these batteries have become increasingly popular in recent years due to their high energy density and long lifespan. The batteries are composed of several layers, including cathodes, anodes, and separators, which are made of various materials to ensure optimal battery performance.

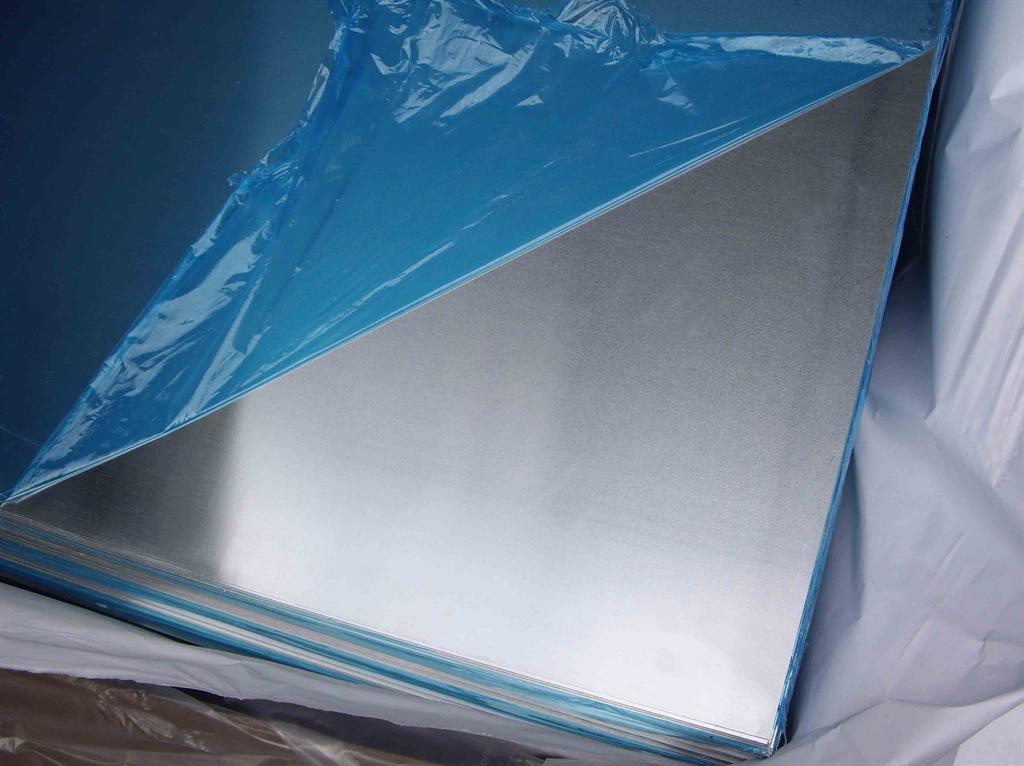

One of the essential components of a lithium battery is the aluminum foil used in the electrodes. This foil is typically made of aluminum or copper and is incredibly thin to allow for flexibility and efficient energy transfer. However, it is not just the thickness of the foil that affects battery performance. Other factors such as the surface area and the quality of the foil can also impact the battery's efficiency and stability.

The thickness of aluminum foil used in a lithium battery typically ranges from 10 to 30 microns, with the most common thickness being around 20 microns. However, manufacturers must consider several factors before deciding on the appropriate thickness of the foil. For instance, a thinner foil can result in better energy transfer, but it may also be more prone to puncturing, which can affect the battery's safety. Conversely, a thicker foil can provide more stability, but it may also decrease the battery's energy efficiency.

Copper foil, on the other hand, is generally thicker than aluminum foil and can range from 4 to 20 microns. The most common thickness is around 10 microns. While the thicker copper foil is more durable and provides stability to the battery, it may also result in a decrease in energy transfer and efficiency. Therefore, manufacturers must consider the unique needs of their battery applications when selecting the appropriate thickness of the foil.

In conclusion, the thickness of aluminum and copper foil used in a lithium battery plays a crucial role in its performance and safety. Manufacturers must carefully evaluate various factors, including energy transfer, stability, and efficiency, before selecting the appropriate thickness of the foil. By following the manufacturer's guidelines and considering the unique needs of their battery applications, manufacturers can ensure optimal battery performance and safety.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog