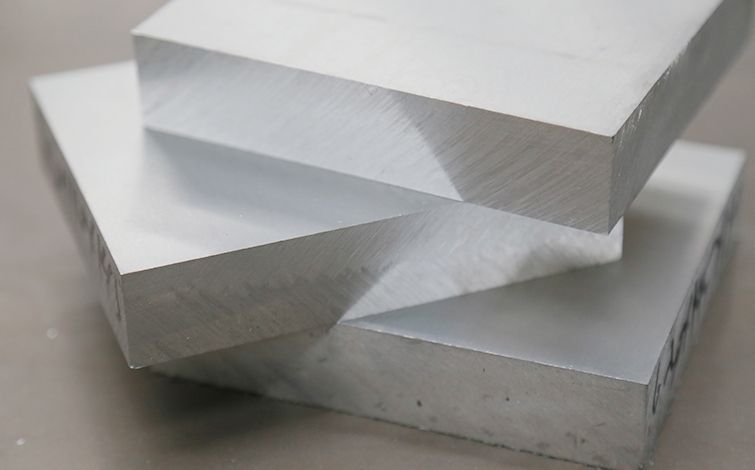

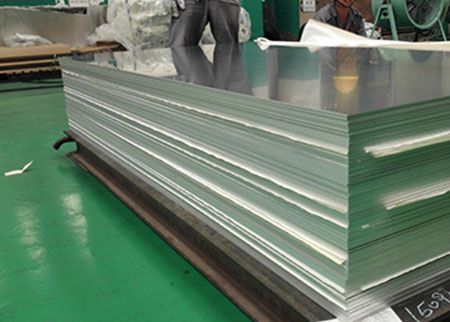

8011 aluminum is a type of aluminum alloy that contains a small amount of iron and silicon. 8011 aluminum sheet and 8011 aluminum foil are highly versatile and is used in various manufacturing applications. Its unique combination of properties makes it an ideal material for a wide range of products.

One of the most common applications of 8011 aluminum is in the packaging industry. Due to its excellent barrier properties, it is widely used in the production of food and beverage packaging. It is commonly used in the production of aluminum foil, bottle caps, and other packaging materials. Its ability to keep food fresh and safe from contamination makes it a popular choice in the food industry.

The use of 8011 aluminum foil in food packaging is increasing due to the growing demand for safe and eco-friendly packaging solutions. The material is recyclable, which reduces the environmental impact of packaging waste. In addition, it is lightweight, which reduces transportation costs and energy consumption.

Another application of 8011 aluminum foil is in the production of heat exchangers. Its high thermal conductivity and corrosion resistance make it an ideal material for use in radiators, air conditioning systems, and other heat transfer applications. Its ability to withstand high temperatures and resist corrosion ensures the longevity of the heat exchangers, making them a reliable and efficient option.

In recent years, the demand for energy-efficient heating and cooling systems has increased, leading to a higher demand for heat exchangers made from 8011 aluminum. The material's high thermal conductivity allows for efficient heat transfer, resulting in lower energy consumption and reduced carbon emissions.

8011 aluminum is also used in the production of various electrical components, such as connectors, capacitors, and transformer windings. Its excellent electrical conductivity makes it an ideal material for use in these applications, ensuring that they function efficiently and reliably.

The use of 8011 aluminum foil in electrical components is growing due to the increasing demand for energy-efficient and reliable electronic devices. The material's electrical conductivity allows for efficient energy transfer, resulting in lower power consumption and longer-lasting devices.

In the construction industry, 8011 aluminum sheet is used for roofing, siding, and other applications that require a lightweight and durable material. Its ability to withstand harsh weather conditions and resist corrosion makes it an ideal choice for use in buildings and structures.

The use of 8011 aluminum in the construction industry is increasing due to the growing demand for sustainable and energy-efficient buildings. The material's lightweight nature reduces the load on buildings, leading to lower construction costs and energy consumption. In addition, its durability and resistance to corrosion ensure that buildings made from 8011 aluminum sheet are long-lasting and require minimal maintenance.

In conclusion, 8011 aluminum is a versatile material that finds applications in various manufacturing industries due to its excellent properties. Its ability to withstand high temperatures, resist corrosion, conduct electricity, and provide lightweight and durable solutions make it an ideal material for use in a wide range of applications.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog