The production process of coated aluminum coil is a complex and precise process that involves various steps. The process requires skilled professionals and specialized equipment to ensure high-quality and durable coatings.

The following are the steps involved in the production process of coated aluminum coil:

The first step in the production process is cleaning and pre-treatment. The aluminum surface is cleaned to remove any impurities and then treated with chemicals to enhance its adhesion and corrosion resistance. This step is crucial as it ensures the coating will bond properly to the aluminum surface and provide maximum durability.

After cleaning and pre-treatment, a layer of primer is applied to the aluminum surface. The primer helps in improving adhesion and durability of the coating. It also provides a smooth surface for the top coat application. The choice of primer depends on the type of coating and the specific requirements of the application.

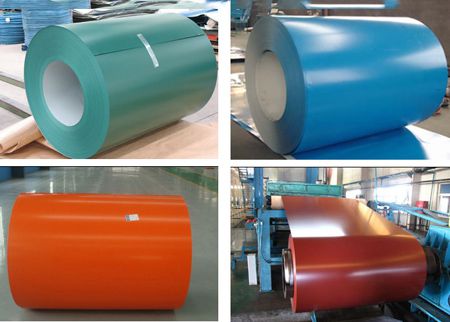

Once the primer is applied, a layer of top coat is applied over it. The top coat provides the desired color, texture, and finish to the coated aluminum coil. The choice of top coat depends on the desired finish, color, and specific requirements of the application.

After the top coat is applied, the coated aluminum coil is then cured in an oven at a specific temperature and time to ensure proper bonding of the coating to the aluminum surface. The curing process is crucial as it ensures the coating is fully bonded to the aluminum and provides maximum durability.

The coated aluminum coil undergoes various quality control tests to ensure that it meets the required specifications and standards. These tests include adhesion, corrosion resistance, hardness, gloss, and color consistency tests. The quality control process is crucial as it ensures the coated aluminum coil meets the required standards and specifications.

Finally, the coated aluminum coil is packed and shipped to the customer. The packaging process is crucial as it ensures the coated aluminum coil is protected during transportation and arrives at the customer's location in good condition.

In conclusion, the production process of coated aluminum coil is a complex and precise process that requires skilled professionals and specialized equipment to ensure high-quality and durable coatings. Each step in the process is crucial, and quality control is essential to ensure the coated aluminum coil meets the required specifications and standards.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog