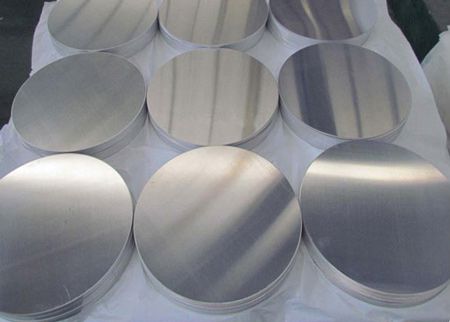

Spinning castings in aluminium alloys for wheels

Spinning casting of aluminium alloys for wheels is a bit like drawing in the ceramic process. It is based on gravity casting or low-pressure casting, where the rim is gradually stretched and thinned by the rotation of the aluminium germ itself and the extrusion and stretching of the spinning tool. The rim is formed by hot spinning and has a clear fibre flow in its organisation, which greatly improves the overall strength and corrosion resistance of the wheel. Due to the high strength of the aluminium alloy material for wheels, the light weight of the product and the small molecular gap in the material, it is a process that is now quite popular on the market.

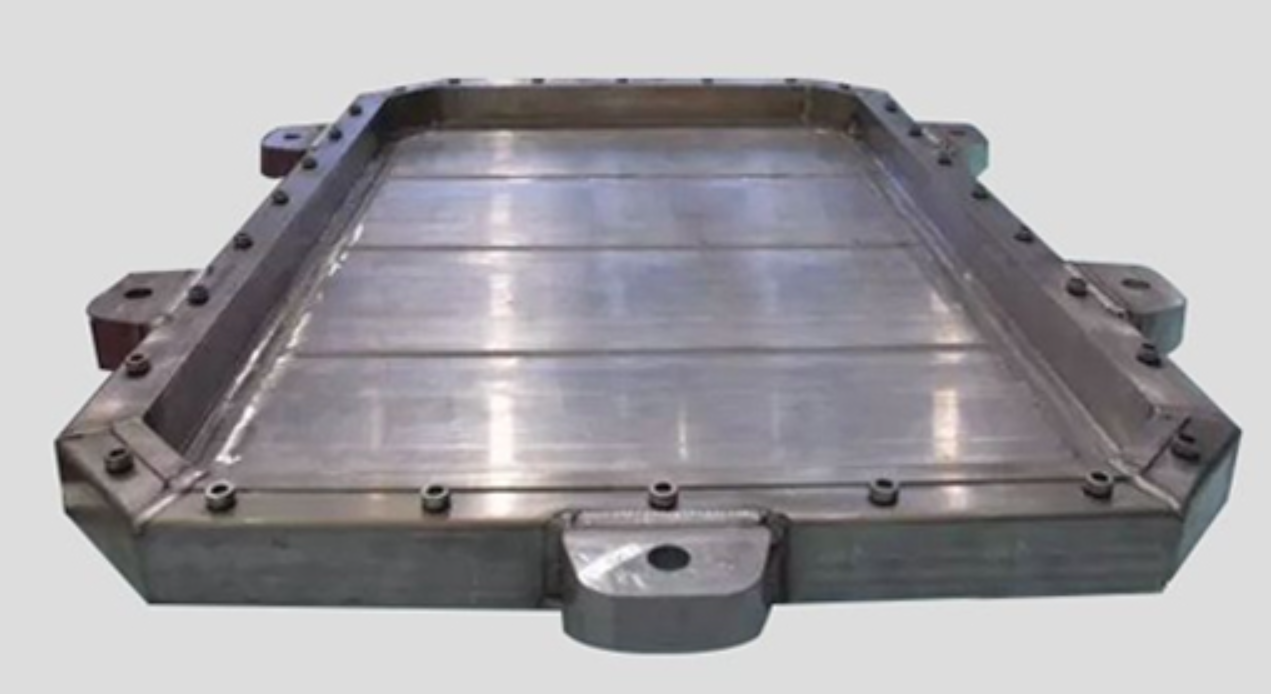

One-piece forging of aluminium alloys for wheels

Forging is a processing method that uses forging machinery to apply pressure to a metal billet to produce plastic deformation in order to obtain forgings with certain mechanical properties and a certain shape and size. Forged aluminium alloys for wheels have a denser internal structure and the forging process allows for a better heat treatment of the metal, resulting in better thermal properties. The forging process can only process a single piece of metal, which cannot be formed into a special shape, and therefore the forging process is followed by a complex cutting and grinding process.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog