3003 water-cooled plate material introduction - Battery water-cooled plate - 3003 aluminium plate for automotive water-cooled plate manufacturers

Water-cooled plates are an important part of the thermal management system of new energy vehicles and are usually used in a load-bearing, corrosion-resistant environment. Therefore, when choosing the material for manufacturing water-cooled plates, the strength and corrosion resistance of the material needs to be considered. Automotive water-cooled plates are generally made from aluminium brazed composites, and the process is mainly raw material stamping - cleaning - flux application - riveting - brazing - testing - sealing and other processes. In order to ensure that the water-cooled plate stamping tensile requirements, the material used has a good tensile capacity. 3003 aluminium sheet has excellent performance, widely used in automotive water-cooled plate material

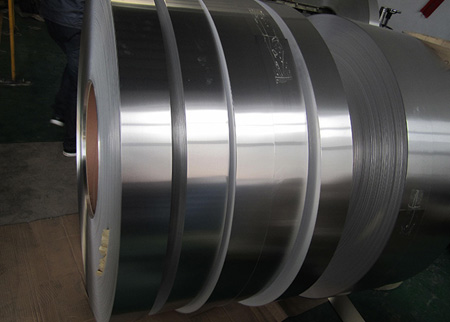

With the development of new energy vehicles, the demand for water-cooled plates will continue to rise, and so will the market demand for 3003 aluminium plate for brazing composites. 3003 aluminium plate's main alloying element is manganese, and the strength of 3003 aluminium plate alloy increases with the increase of manganese content. 3003 aluminium plate has good formability, good corrosion resistance and weldability. Mingtai Aluminium offers aluminium sheets in various thickness states: 0.2-500mm, width 100-2500mm, on request.

What are the advantages of using 3003 aluminium sheet for automotive water-cooling plate?

1. Light weight. Aluminium alloy has the advantages of low density, high specific strength, easy processing and forming, etc., which is the ideal material for light weight automobile at present.

2. Excellent corrosion resistance. 3003 aluminum plate belongs to the aluminum-manganese alloy series, also known as rust-proof aluminum plate, still has good rust-proof ability in wet environment.

3. Good stamping and drawing properties. 3003-O state aluminium sheet is soft and malleable, easy to punch and stretch, in line with conventional processing requirements.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog