If you're looking for a 1060 aluminum strip manufacturer in China, there are several ways to find one. You can start by searching online directories and marketplaces such as Alibaba, Made-in-China, and Global Sources. These platforms have a vast network of suppliers, manufacturers, and wholesalers from different parts of the world. You can filter your search by location, product type, and other relevant criteria to find the right supplier for your needs.

Another option is to attend trade shows and exhibitions, such as the Canton Fair, to meet with potential manufacturers in person. These events provide an opportunity to network with industry professionals, learn about the latest trends and technologies, and explore different product options. You can also get a firsthand look at the quality of the products, ask questions, and establish relationships with suppliers that can help you in the long run.

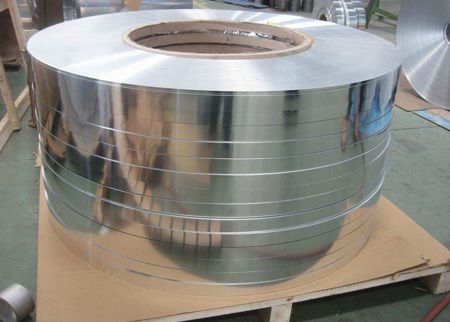

When it comes to choosing between copper strip and aluminum strip for transformers, there are pros and cons to both options. Copper is a better conductor of electricity than aluminum, which means it can handle higher electrical loads without overheating. This property makes it the preferred choice for high-power transformers that require a lot of current. Copper is also more durable, resistant to corrosion, and has a longer lifespan than aluminum.

However, copper is also more expensive than aluminum and heavier, which can increase the overall weight and cost of the transformer. This cost factor makes aluminum more attractive for smaller transformers and those that don't require as much electrical current. Aluminum is also more lightweight, which makes it easier to handle, transport, and install. It is also less prone to thermal expansion, which can reduce the risk of mechanical failure in the transformer.

On the other hand, aluminum has a lower conductivity than copper, which means it may not be as efficient as copper in some applications. This lower conductivity can lead to energy losses, reduced power output, and increased operating costs over time. However, advances in technology and design have made it possible to optimize aluminum's conductivity and minimize these losses.

Ultimately, the choice between copper strip and aluminum strip for transformers will depend on the specific needs of your project. Factors such as power requirements, cost, weight, durability, and efficiency will all play a role in the decision-making process. If you need help deciding which option is best for you, it's a good idea to consult with a qualified engineer or transformer manufacturer who can provide expert advice and guidance based on your specific needs and requirements.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog