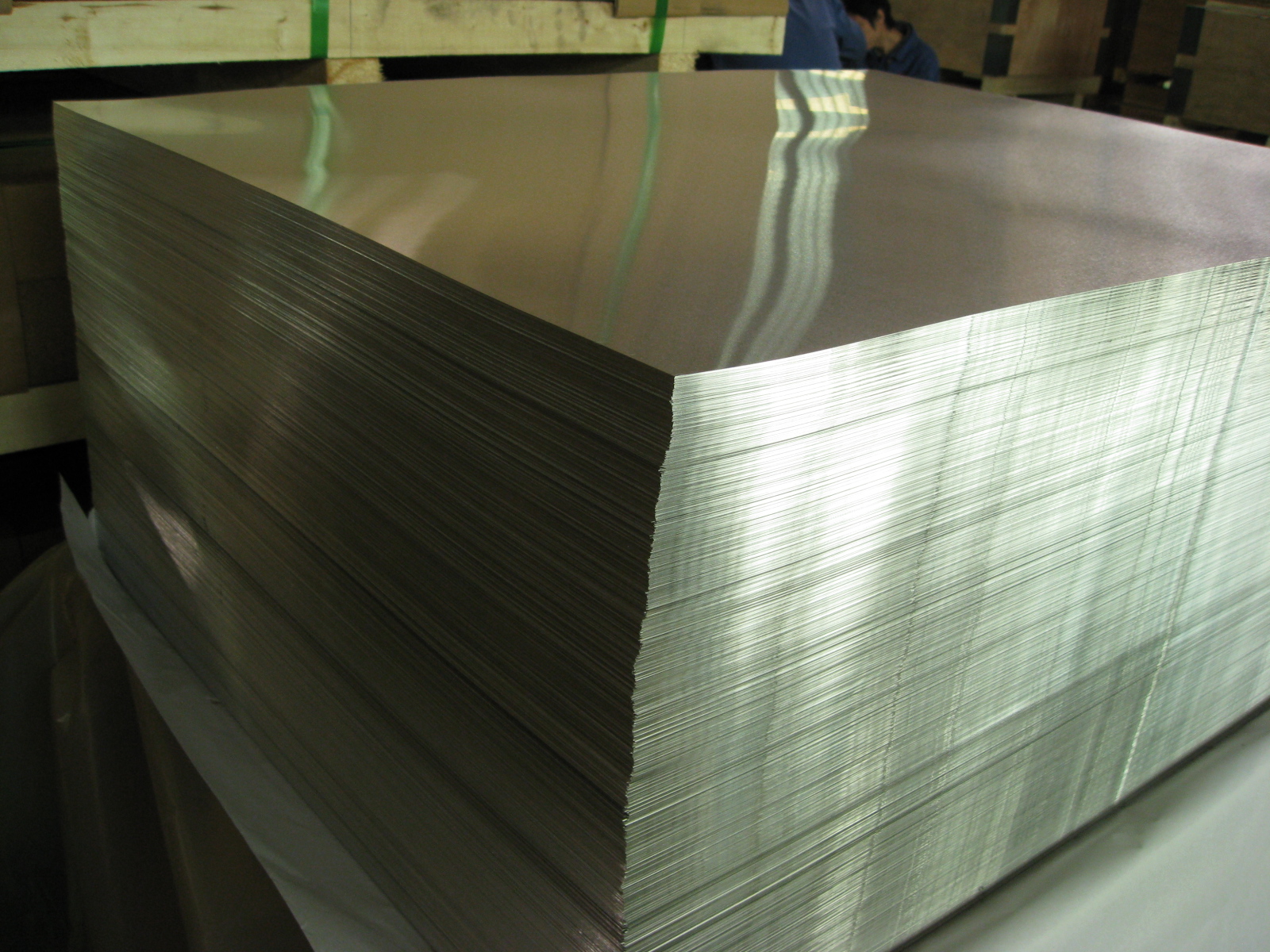

As we mentioned last time, the surface of aluminium sheet can be finished in many ways, including brushed metal. This gives a fine hairline sheen to the matt metal, giving the product a stylish and technical look.

A further technique is high-gloss cutting. The diamond cutter is reinforced by a precision engraving machine on a high-speed (typically 20,000 rpm) precision engraving machine spindle to cut the part, creating a localised highlight area on the surface of the product. The brightness of the cut highlights is influenced by the speed of the milling drill, the faster the drill speed the brighter the cut highlights, and vice versa the darker and more prone to tool marks.

High-gloss cutting is particularly used in mobile phones, such as the iPhone 5, and in recent years some high-end TV sets have adopted high-gloss milling processes for their metal frames, combined with anodising and brushing processes to give the whole aluminium plate of the TV set a sense of style and technological sharpness.

Anodising is also a form of surface finishing for aluminium products. Anodising is the electrochemical oxidation of a metal or alloy, where aluminium and its alloys are subjected to a corresponding electrolyte and specific process conditions to form an oxide film on the aluminium product (anode) due to the action of an applied current. Anodising not only solves the defects of the aluminium surface in terms of hardness and wear resistance, but also prolongs the service life of the aluminium and enhances its aesthetics, making it an indispensable part of the surface treatment of aluminium sheets. Two-colour anodising is the process of anodising a product and giving a different colour to a specific area. Two-colour anodising is more costly because of the complexity of the process; however, the high-end, unique aluminium sheet appearance of the product is better reflected through the contrast between the two colours.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog