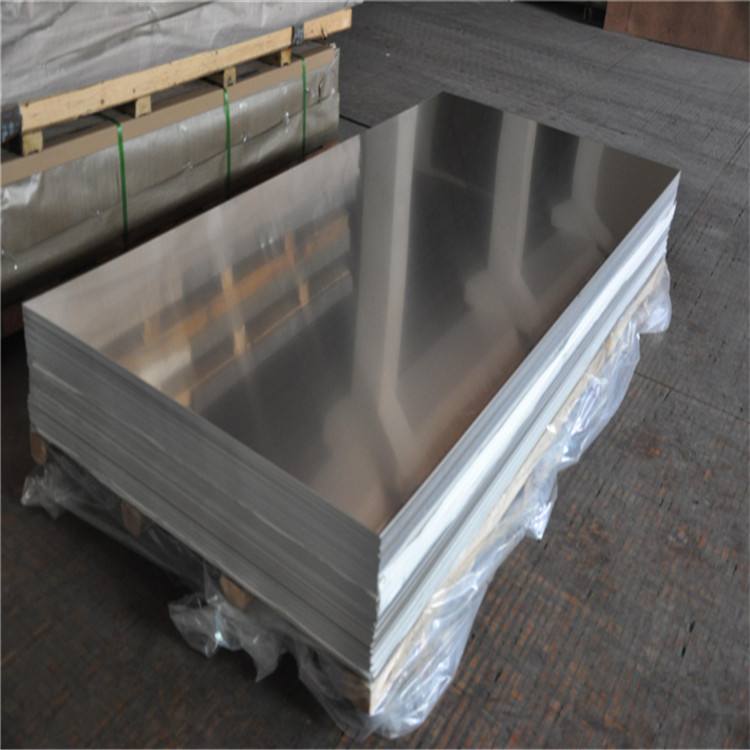

Aluminum sheets are widely used in various industries due to their light weight, high strength, and excellent corrosion resistance properties. Among the different types of aluminum sheets, 1050, 1060, 1070, and 1100 are some of the most commonly used ones. In this essay, we will discuss the differences among these four types of aluminum sheets and their respective applications.

1050 aluminum sheet is the purest form of aluminum among the four mentioned types. It has a purity of 99.5%, which makes it highly suitable for applications that require excellent electrical conductivity, such as transformers and capacitors. Additionally, 1050 aluminum sheet has good formability, weldability, and corrosion resistance. Due to these properties, it is also used in various other applications, such as kitchenware, reflectors, and signage.

1060 aluminum sheet is another pure form of aluminum, with a purity of 99.6%. It has similar properties to 1050 aluminum sheet, including good formability, weldability, and corrosion resistance. However, 1060 aluminum sheet has slightly better strength than 1050 aluminum sheet. Due to these properties, it is commonly used in the manufacturing of household appliances, heat sinks, and utensils.

1070 aluminum sheet is an alloy that contains 99.7% aluminum and 0.3% copper. The addition of copper improves the strength and hardness of the alloy, making it suitable for applications that require high strength, such as heat exchangers and electrical conductors. Additionally, 1070 aluminum sheet has good formability and corrosion resistance, making it suitable for use in the food and chemical industries.

1100 aluminum sheet is an alloy that contains 99% aluminum and 1% other elements, such as copper, iron, and silicon. It has good formability, weldability, and corrosion resistance properties, making it suitable for a wide range of applications, such as packaging, roofing, and insulation. Additionally, 1100 aluminum sheet is highly reflective, making it suitable for use in lighting and decorative applications.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog