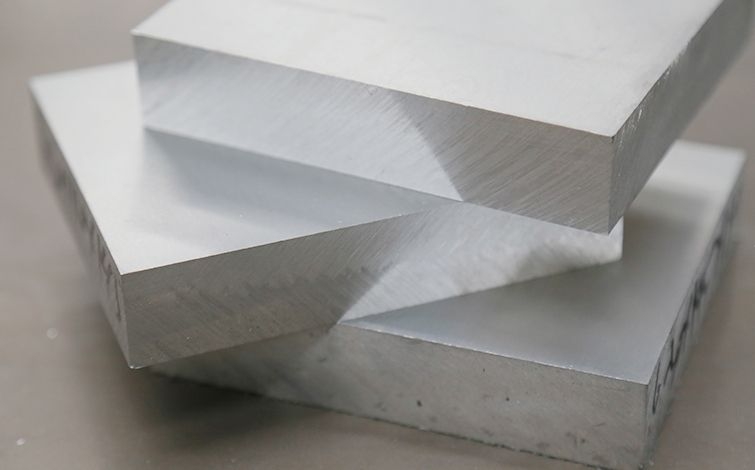

The control of melting temperature in the manufacture of aluminum plate for sale Haomei

Melting temperature is too low, is not conducive to the dissolution of aluminum alloy elements and gas, inclusions discharge, increase the formation of segregation, cold isolation, the tendency of under-casting, but also due to the lack of heat at the mouth, so that the casting does not have a reasonable complementary shrinkage. So in the melting process to control the melting temperature is essential. So how should we be able to control the temperature? Let's take a look at it together today!

Some information points out that the melting temperature of all aluminium alloys should reach at least 705 degrees and should be stirred. The melting temperature is too high not only to waste energy, but also because the higher the temperature, the more hydrogen is absorbed, the more coarse the grain is, the more serious the oxidation of the aluminium plate is, and the more serious the burning of some alloy elements is, which leads to the decline of the mechanical properties of the alloy, the deterioration of the casting performance and machining performance, the weakening of the effect of the transformation process, and the reduction of the air tightness of the casting.

Production practice proves that the alloy liquid is quickly warmed up to a higher temperature, reasonable stirring to promote the dissolution of all alloying elements (especially refractory metal elements), pick up the floating slag and then drop to the pouring temperature, so that the degree of segregation is minimal, the molten hydrogen is also less, which is conducive to obtaining uniform and dense, high mechanical properties of the alloy for sale. Because the temperature of the aluminium plate and the aluminium melt is difficult to judge with the naked eye, the temperature should be controlled by temperature measuring instruments, regardless of the type of melting furnace used. Temperature measuring instruments should be regularly calibrated and serviced. Thermocouple sleeves should be periodically cleaned with a metal brush and coated with protective paint to ensure the accuracy of the temperature measurement results and the longevity of the service.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog