Knowledge about melting aluminium plates

We have already introduced a lot of knowledge about the selection and quality control of aluminium alloy charges, but there are many other matters that need our attention during the melting process of aluminium sheets, so today we will briefly introduce the management and storage of charges and the preparation of crucibles and melting tools, which will help other aluminium sheet manufacturers to better process aluminium alloys and sheets, and customers who buy them to understand the processing principles and to be able to better The customer who buys them understands the principles of the process and is able to select the product.

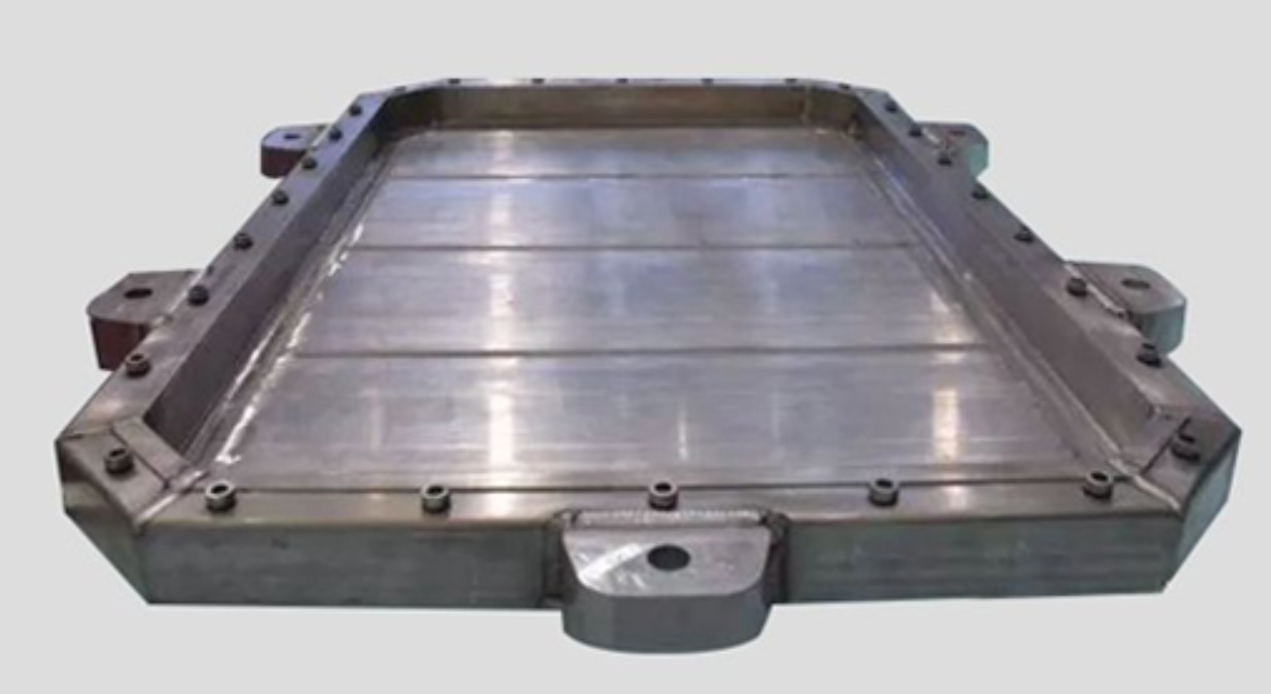

First of all our charge needs to be stored and managed properly, which is important to ensure the quality of the alloy and the aluminium sheet. The furnace charge should be stored in a dry warehouse where the temperature does not vary much. Next we introduce the preparation of crucibles and melting tools. Crucibles are commonly used for casting aluminium alloys in iron, but also in cast steel and welded steel plates. New crucibles and old crucibles that have not been used for a long time should be sand blown before use and heated to 700 - 800 degrees and kept for 2 - 4 hours in order to burn out the moisture and combustible material attached to the inner wall of the crucible, to be cooled to below 300 degrees, carefully clean the inner wall of the crucible and spray paint when the temperature is not lower than 200 degrees. The crucible should be preheated to a dark red colour (500 - 600 °C) and kept warm for more than 2 hours before use. Before melting outside the new crucible, it is advisable to melt a furnace of the same aluminium plate grade back into the furnace.

Next we look at the preparation of the melting tools. In general, we need bellows, press ladles, stirring spoons, pouring ladle ingot moulds, etc. They should all be preheated before use and coated with a protective coating at a temperature of 150 degrees - 200 degrees and dried thoroughly at a drying temperature of 200 - 400 degrees with a holding time of 2 hours or more. After use, the oxides and fluorides attached to the surface should be thoroughly removed, (preferably by sand blowing).

This is about the aluminum plate melting process some details of the problem! I hope it can help you.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog