Pre-treatment of anodised aluminium alloy sheets for sale Haomei

Before anodising, we need to carry out a series of treatments on the aluminium alloy sheet in order to achieve the best possible final anodised aluminium sheet, and this process is called pre-treatment of aluminium alloy sheet anodising. How should we pre-treat the aluminium alloy plate? How many methods are there? What materials are used? What kind of anodised aluminium sheet can we get after the treatment? Let's take a look today!

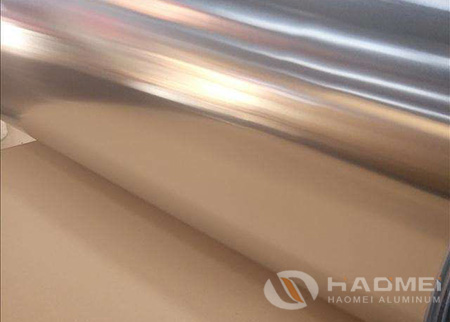

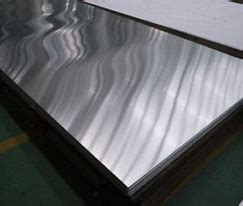

The surface treatment of aluminium is a series of mechanical and chemical surface pretreatment processes and the combination of surface film treatment processes. Anodized aluminum surface pretreatment methods are mechanical and chemical (or electrochemical) methods of two categories. Mechanical methods include sandblasting, brushing, sweeping and polishing, etc.; chemical methods include degreasing, alkaline washing, matt treatment, etc. The surface film-forming technology of aluminium mainly includes anodic oxidation, chemical transformation, electroplating and chemical plating and organic coating. Chemical conversion includes chroming, phosphor chroming and chromium-free chemical conversion, which is suitable as a base layer for organic polymer coating. All of these allow alloy aluminium sheets to maintain a smoother and flatter surface and a good looking appearance when being processed.

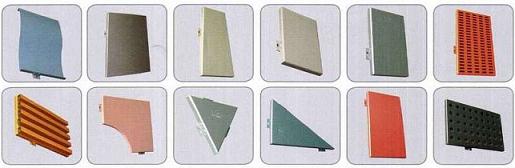

It should also be noted that some profiles have different colours, which are not oxidised, but are formed after the aluminium has been anodised and dyed or electrolytically coloured. Dyeing is basically any colour, while electrolytic colouring is less common, and can be done in black, bronze, champagne, gold or stainless steel.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog