Analysis of the characteristics of brushed oxide aluminum plate in aluminum oxidation processing

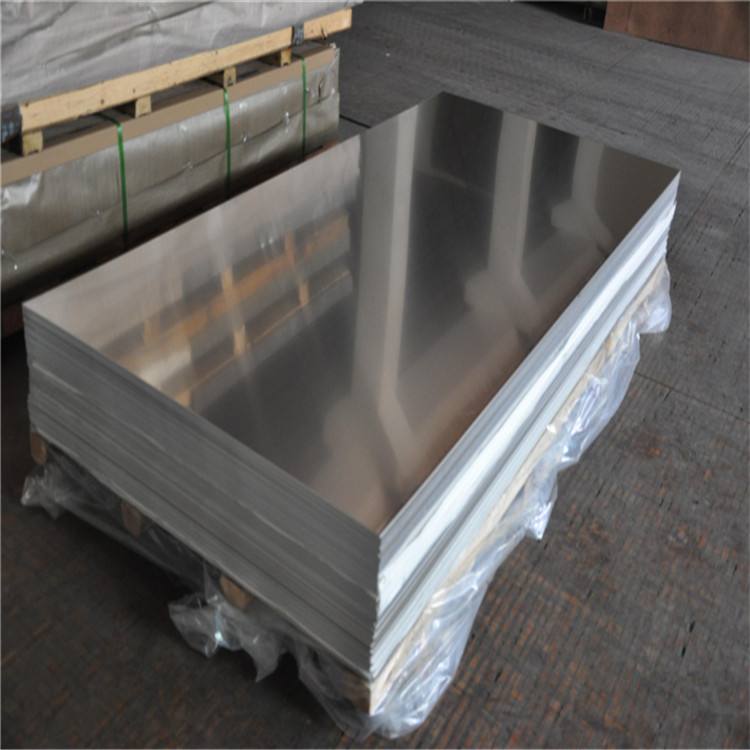

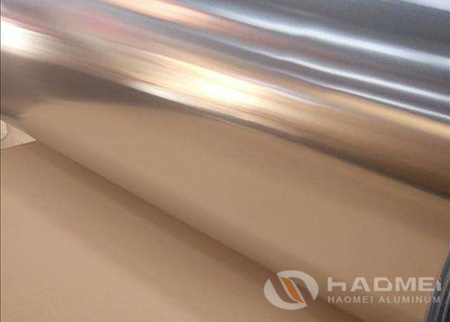

Oxidized brushed aluminum plate is a manufacturing process that repeatedly scrapes out the lines of aluminum plate with sandpaper, and its main process is divided into three parts: deesterification, sand mill and water washing. In the wire drawing process of aluminum plate, the special film technology after anodic treatment can generate a film layer containing the metal component on the surface of the aluminum plate, clearly showing every fine silk mark, so that the metal matte shines with fine hair.

Oxide brushed aluminum plate is widely used in lighting fixture reflector and lamp decoration, solar collector reflective materials, interior architectural decoration, exterior wall decoration, household appliance panels, electronic product shells, furniture kitchens, automotive interior and exterior decoration, signs, signs, bags, jewelry boxes and other fields.

Features of oxide brushed aluminum plate

1. No discoloration, no corrosion, no oxidation, if the oxide film on the surface of the brushed aluminum plate reaches more than 10 um, it will not change color when used outdoors for long-term exposure to the sun's rays.

2. The surface hardness of the oxide brushed aluminum plate reaches the gem level, good scratch resistance, strong decoration, highlights the modern metal sense, and improves the product grade. Continuous high-speed stamping, no more complex surface treatment, convenient direct processing into products, can shorten the product production cycle and reduce product production costs.

3. High temperature resistance, no harmful gases will be produced at high temperatures, safe and environmentally friendly. It does not leave a handprint after touching it by hand, is easy to clean, and does not produce corrosive spots.

In the pressure processing of aluminum plate, under the action of external force, the aluminum plate is forced through the mold, the metal cross-sectional area is compressed, and the technical processing method of obtaining the shape and size of the required cross-sectional area is called aluminum plate wire drawing process, and the tool that makes it change the shape and size is called wire drawing die.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog