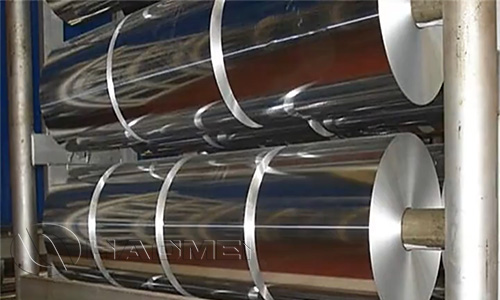

Oxidation film in the casting of aluminium alloy profiles such as Haomei aluminium discs

The oxide film can play a very important role in the production of aluminium discs. Due to the presence of an oxide film on the surface of the molten metal and the fact that this film is very dense, it prevents the diffusion of gases into the interior of the aluminium round sheet metal, slowing down the dissolution rate considerably. If the oxide film is damaged, it will inevitably accelerate the absorption of gas by the metal. So any operation that destroys the oxide film on the surface of the melt during the melting and casting process is detrimental.

For any chemical reaction, the time factor always favours the continuity of a reaction, which eventually reaches its saturation of the gas dissolved in the aluminium disc metal. Therefore, the longer the exposure time in any case, the more gas is absorbed. In particular, the prolonged exposure of the melt at high temperatures increases the chances of aspiration. Therefore, during the melting process, always aim to reduce the melting time in order to minimise the gas content of the melt so that we can harvest good aluminium discs. And our cast aluminium discs can be refined and deepened in the next step according to customer requirements.

We are a very good producer and manufacturer of aluminium discs, which are well manufactured and can be supplied in a variety of sizes and colours. Please contact us if you would like to purchase.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog