Die-casting integration of all-aluminum body: born out of thin air, bursting elasticity

Die-casting integrated industrial chain belongs to the secondary acceleration industry in the process of automobile lightweight and new energy development, Tesla proposed the concept of integrated die casting of the body, the integrated die casting of the rear floor reduces the cost by 40%, improves production efficiency, saves 35% of the production line production space, and greatly solves the cost and technical problems of the all-aluminum body. At present, in addition to Tesla, NIO, Xpeng and other car companies have begun to invest in the research and development of integrated die casting, which is expected to become an important innovation that changes the industry ecology. It is estimated that in 2025, the market size of die-casting parts for all-aluminum body new energy vehicles and traditional fuel vehicles in China is expected to reach 10.78 billion yuan and 2.08 billion yuan, of which the CAGR corresponding to new energy passenger vehicles in 2021-2025 is about 109.1%.

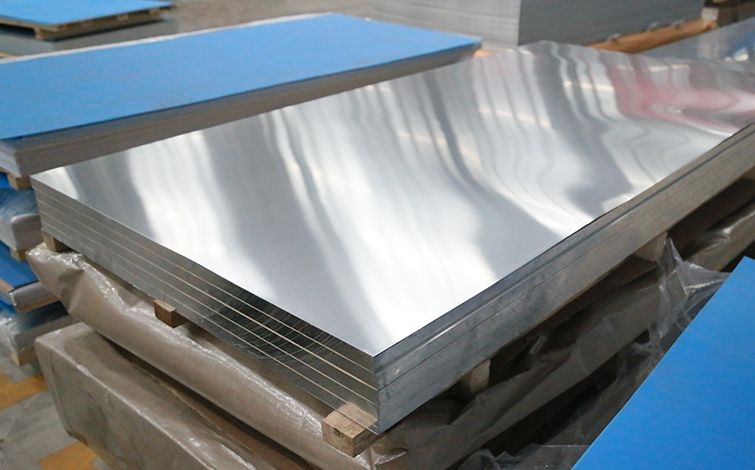

1) The amount of aluminum alloy integrated die casting used and the price of aluminum alloy

Referring to the current research and development progress, the future integrated die-casting process will be applied to the battery box, subframe, motor housing and other components in addition to the rear underbody, according to the aforementioned part of the weight calculation, it is expected that the weight of the all-aluminum body new energy vehicle integrated die-casting process components can reach 100KG in 2025. According to DuckerFrontier research, pure electric vehicles due to the power system and body structure parts use more aluminum alloy, new energy vehicles use 41.6% more aluminum alloy than traditional fuel vehicles, and there is no motor, battery box and other components needed, assuming that the weight of traditional fuel vehicle integrated die-casting process parts in 2025 is about 70kg. At present, the price of aluminum alloy is 2-5 times that of steel, on the one hand, the price of aluminum alloy materials is expected to decline in the future with the maturity of technology, on the other hand, with the development of lightweight automobiles, the performance requirements of automotive aluminum alloys will be higher. Referring to the proportion of raw material costs and gross profit margins disclosed in the prospectuses of Wencan Shares, Xusheng Shares and Ikedi, it is reasonable to assume that the price of all-aluminum body and automotive aluminum alloy will remain at 7 dollars/kg in the future.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog