Comparison of processing and production methods of aluminium sheets and their advantages and disadvantages

China is a large producer and consumer of aluminium alloy materials. Aluminium alloy materials are widely used in transportation, marine, air and space fields, especially in some lightweight key components of automobiles, aircraft, aerospace, ships and other fields, aluminium alloy materials are irreplaceable, so today we will talk about the processing and production methods of aluminium sheets and the comparison of advantages and disadvantages.

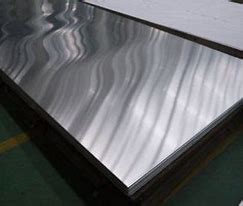

Method 1: Block method

Brief description of the process: Shearing into slabs of a certain length after hot rolling or cold rough rolling, and then using cold rolling and other processes until the finished product.

Advantages: simple equipment and operation, low investment, quick start, and flexibility in the variety and specifications produced.

Disadvantages: low productivity and yield, high labour intensity, poor production conditions, long lead times and limited output.

Overall assessment: relatively old method, suitable for small to medium sized plants and for the production of panels with larger specification requirements.

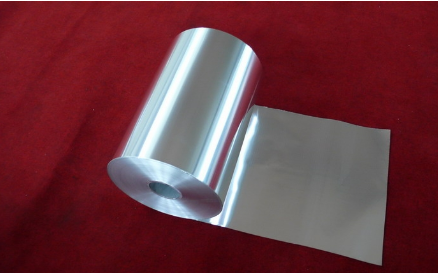

Method 2: Belt method

Brief description of the process: Rolled in coils and finally sheared transversely into aluminium sheets.

Advantages: large ingots and high rolling speeds can be used, the production process can be automated and continuous, productivity and yield are high, and labour intensity is low.

Disadvantages: complex equipment, large investment, long construction period, more homogeneous varieties.

Comprehensive evaluation: emerging production method, catering to the current demand for continuous expansion of the scale level of aluminium sheet processing enterprises.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog