Aviation aluminium foil lunch boxes

As a safe, hygienic and environmentally friendly material, the important feature of aluminium foil as a packaging material is its excellent barrier performance, effectively blocking air, water and light, thus maintaining or extending the shelf life and freshness of food. Aviation aluminium foil boxes are generally made of 8011 or 3003 alloy aluminium foil through punching and moulding in a single press. Its products have a certain degree of hardness, the products are moderately priced and single-use, and aluminium foil is a recyclable, environmentally friendly and infinitely recyclable material. Aluminium foil has excellent heat transfer properties, just to meet the need for short range and fast heating.

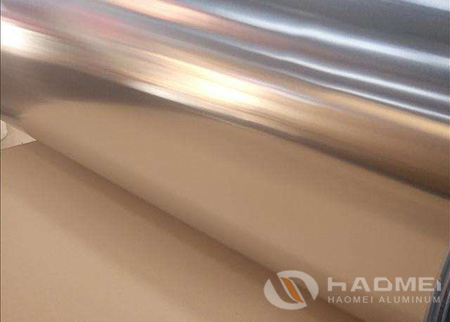

Aviation aluminium foil lunch boxes are classified in terms of appearance quality and can be divided into two types: one is a wrinkled lunch box directly stamped from light foil, the thickness of which is generally 0.06~0.07mm, and the other is a coated aluminium foil lunch box, the thickness of which is generally 0.08~0.09mm. The coating material is a food-grade resin coating, and the transparent or white coating is attached to the aluminium foil through high temperature coating, so that the aluminium foil is isolated from the air and avoids This prevents the foil from oxidising and becoming black. This is why most airlines use these coated aluminium foil boxes to provide meals to passengers.

Zhengzhou Haomei Aluminium Co., Ltd. is a manufacturer specialising in aluminium foil container products, aluminium foil container moulds and aluminium foil production lines. We welcome you to contact us at any time if you have questions.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog