Many people will ask, is there any aluminum plate made of 100% pure aluminum for sale? The answer is, yes, yes, but it is not widely used. Why do we call industrial pure aluminum, that is, 1-series aluminum alloy sheets always contain other metal and non-metal elements? So let's introduce it today!

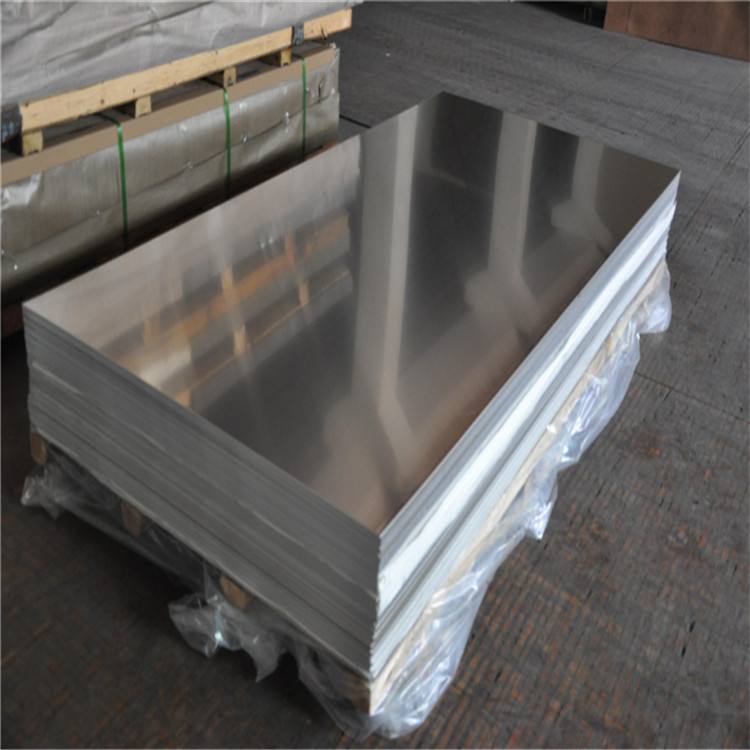

First, let's take a look at the material structure of pure aluminum. The density of pure aluminum is small (ρ=2.7g/cm3), about 1/3 of that of iron, and the melting point is low (660℃). Aluminum is a face-centered cubic structure, so it has high plasticity (δ: 32~40%, ψ: 70~90%), easy to process, can be made into various profiles and plates, and has good corrosion resistance. However, the strength of pure aluminum is very low, and the σb value in the annealed state is about 8kgf/mm2, so it is not suitable for structural materials. Through long-term production practice and scientific experiments, people gradually strengthen aluminum by adding alloying elements and applying heat treatment, which results in a series of aluminum alloys.

Let's take a look at the advantages of aluminum alloys such as industrial pure aluminum that contain other components. Aluminum alloy has low density, but relatively high strength, close to or surpassing high-quality steel, good plasticity, can be processed into various profiles, has excellent electrical conductivity, thermal conductivity and corrosion resistance, widely used in industry, and its usage is second only to steel . The alloys formed by adding certain elements can maintain high strength while maintaining the advantages of pure aluminum and light weight, and the σb values can reach 24-60kgf/mm2 respectively. This makes its "specific strength" (ratio of strength to specific gravity σb/ρ) better than many alloy steels, making it an ideal structural material, widely used in machinery manufacturing, transportation machinery, power machinery and aviation industry. , skin, compressor, etc. are often made of aluminum alloy to reduce the weight. Using aluminum alloy to replace the welding of steel plate material, the structural weight can be reduced by more than 50%. Some aluminum alloys can be heat treated to obtain good mechanical properties, physical properties and corrosion resistance. Hard aluminum alloy belongs to AI-Cu-Mg system, generally contains a small amount of Mn, and can be strengthened by heat treatment. It is characterized by high hardness, but poor plasticity. Super hard aluminum belongs to the Al-Cu-Mg-Zn system, which can be strengthened by heat treatment and is the aluminum alloy with the highest strength at room temperature. However, the corrosion resistance is poor, and the high temperature softens quickly. Forged aluminum alloys are mainly Al-Zn-Mg-Si alloys. Although there are many types of added elements, the content is small, so they have excellent thermoplasticity and are suitable for forging, so they are also called forged aluminum alloys.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog