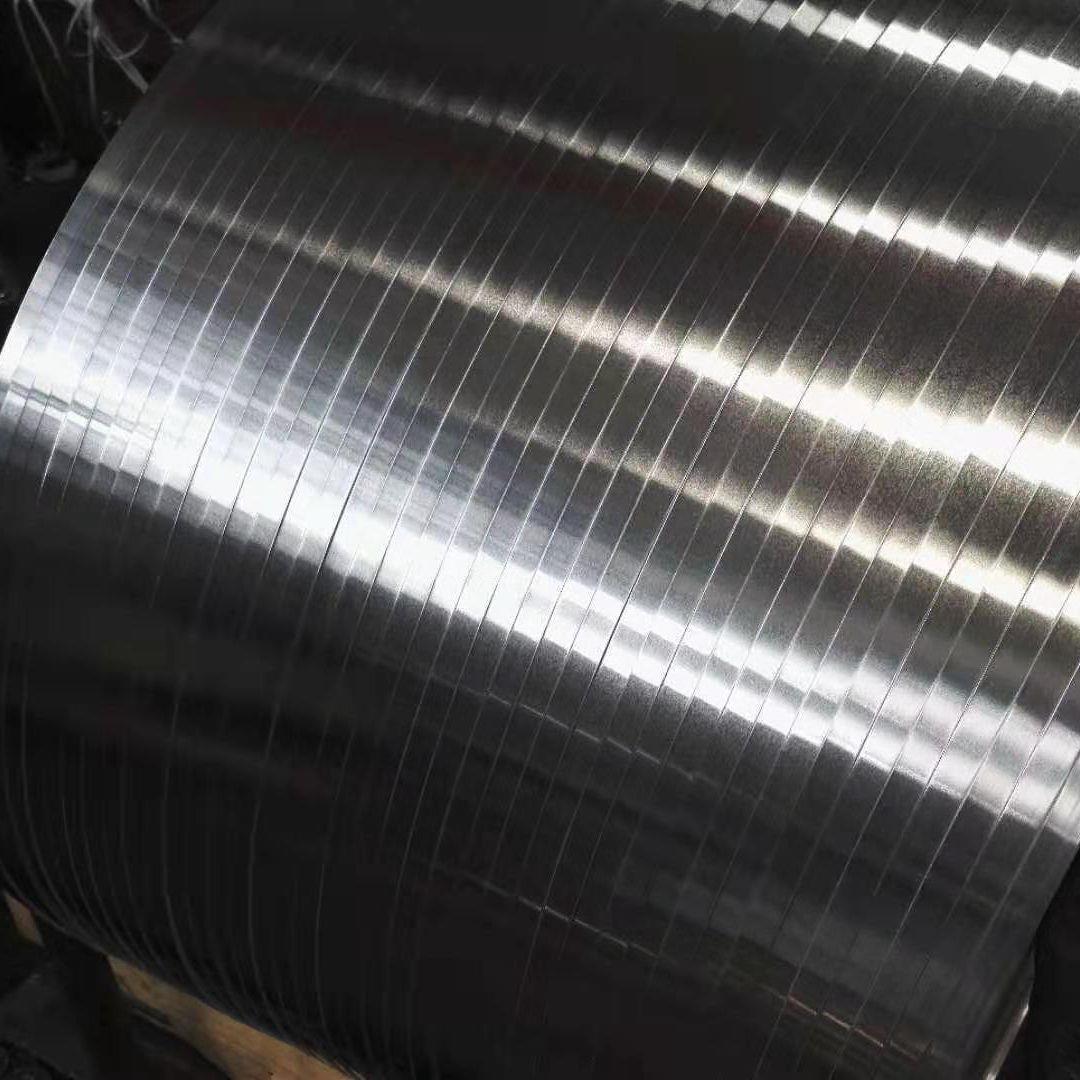

Cars are complex machines that require a combination of materials to achieve the best performance, fuel efficiency, and safety. One of the most important materials used in car manufacturing is aluminium and aluminum plate, which has become increasingly popular due to its unique combination of strength, durability, and lightweight properties.

Although there are other metals, including titanium, that are stronger and lighter than aluminium, car chave found that aluminium alloys offer a good balance of strength and weight, making them ideal for use in car bodies, engines, and other components. Aluminium alloys are made by combining aluminium with other metals, such as copper, magnesium, and zinc, which allows manufacturers to tailor the material to specific applications.

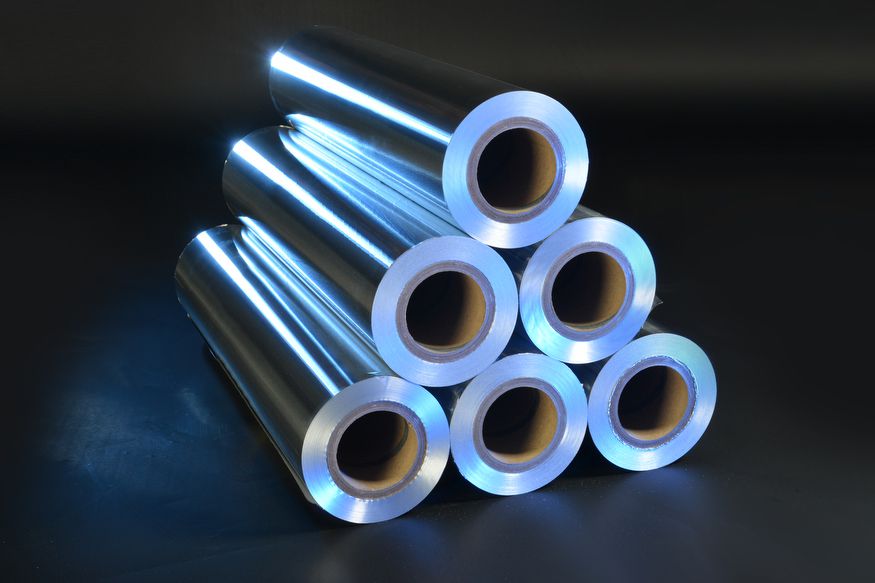

Moreover, aluminium plate is more readily available than titanium, which makes it less expensive and easier to source. Titanium is a rare metal that is difficult to extract and refine, which makes the cost of producing it much higher than that of aluminium. Additionally, titanium is more difficult to work with than aluminium, which adds to the cost of manufacturing and makes it impractical for widespread use in cars.

Another advantage of aluminium is that it is highly resistant to corrosion, which is important for car manufacturers, as cars are often exposed to harsh weather conditions and road salt. Unlike other metals, such as iron and steel, aluminium does not rust or corrode easily, which helps to extend the lifespan of car components and reduce maintenance costs.

Furthermore, aluminium plate has excellent thermal conductivity, which helps to dissipate heat away from high-stress components like engines and brakes. This property of aluminium makes it ideal for use in heat exchangers, radiators, and other cooling components, which play a vital role in keeping the engine and other parts of the car operating at optimal temperatures.

Overall, while there are certainly stronger and lighter materials available, aluminium remains the most practical and cost-effective choice for car manufacturers looking to achieve the optimal balance of weight, strength, and durability in their vehicles. By using aluminium alloys, car manufacturers can create lighter and more fuel-efficient cars that are also safe, reliable, and long-lasting.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog