Aluminium alloy coil can be affected by a number of conditions that can lead to quality problems when they are cast and rolled. In order to ensure that our customers get the best quality aluminium alloy coils, we would like to introduce you to some of the common quality problems that occur when aluminium coils are cast and rolled, namely air and slag streaks, small long cracks, black streaks and scratches. Let's take a look!

Firstly, let's take a look at the air and slag in aluminium alloy coils. Some of the possible causes of these defects during casting and rolling include: poorly executed production processes (inadequate refining), inadequate out-of-furnace de-gassing (leaking de-gassing box), inadequate aluminium water treatment, inadequate filtration (filter box not working properly), and too much moisture in the air. For such potential problems, our recommended corrective measures include: one-time feeding, spreading of covering agent according to the operating process, strengthening of refining, solving the problem of air leakage from the de-gassing box, clean aluminium water treatment, and adding a filtering device to ensure that the aluminium water is filtered.

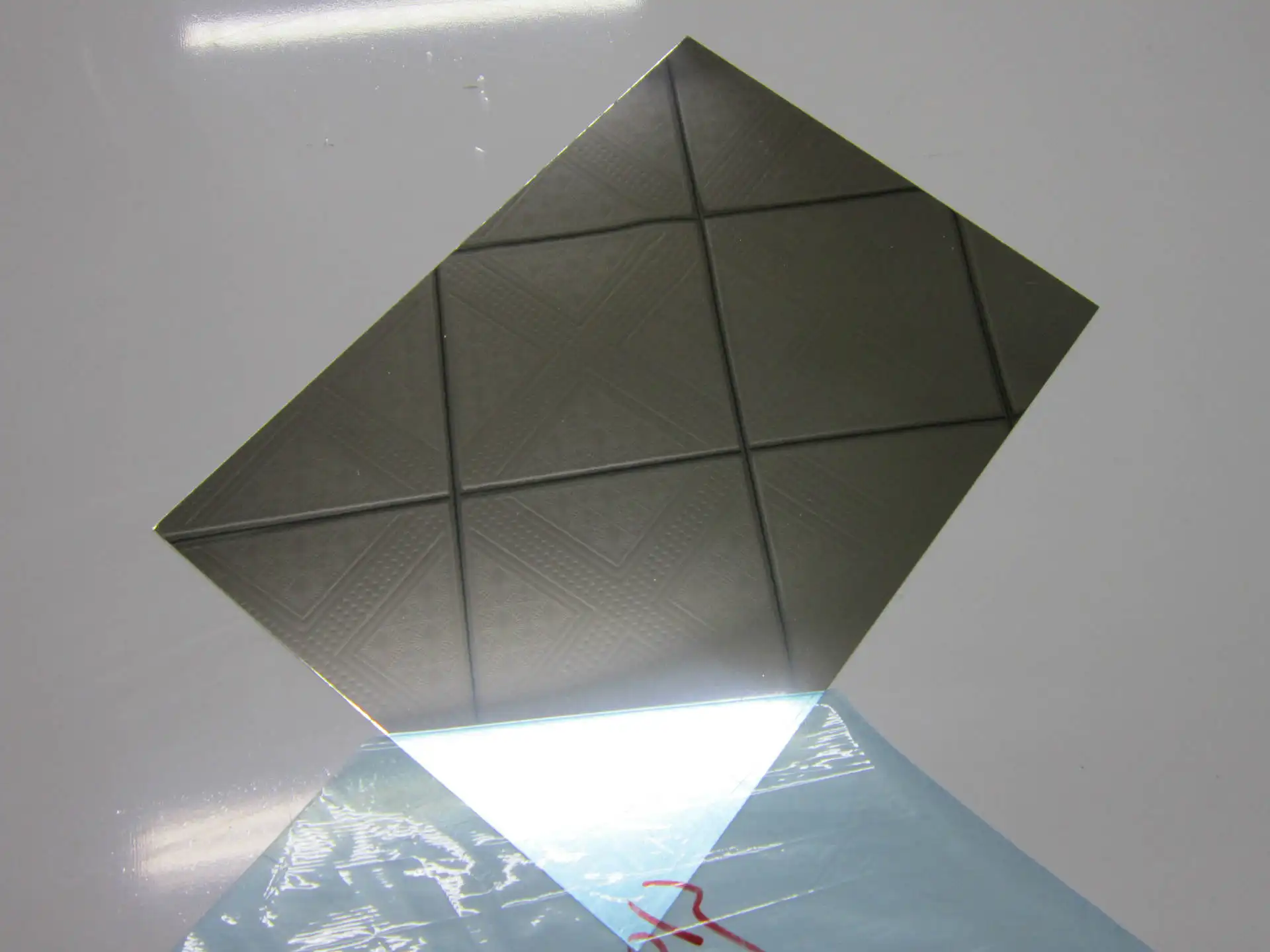

The second problem that can occur with aluminium alloy coils during casting and rolling is the long, small cracks. These defects can be caused by damage to the skin or damage during rolling. The recommended corrective action for such potential problems is to break the sheet immediately if there are any such problems and to ensure that the sheet is intact at the time of production.

The third problem that can occur with aluminium alloy coils during casting and rolling would be black bars. Possible causes of these defects during casting and rolling include: poorly executed processes and poorly treated aluminium water. The recommended corrective measures for such potential problems include: developing the production process and improving the treatment of the aluminium water.

A fourth potential problem with aluminium alloy coils during casting and rolling would be scuffing. The potential causes of these defects during rolling include the abrasion of the surface of the aluminium sheet by the undercutting table. The recommended corrective action for such a potential problem is to rectify the undercutting surface of the shear.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog