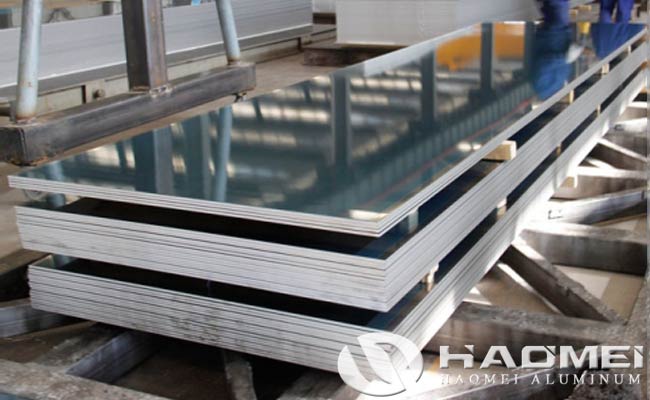

Today we are talking about the welding difficulties of 7 series aluminium alloy materials for sale Haomei. Aluminium and aluminium alloys have low density, high strength, high thermal and electrical conductivity, high corrosion resistance and good physical and mechanical properties, and are therefore widely used in the welded structure of industrial products. For a long time, due to improper selection of welding methods and welding process parameters, it causes serious deformation of aluminium alloy parts after welding due to excessive stress concentration, or because of defects such as weld porosity, slagging and failure to weld through, resulting in cracking of weld metal or material loosening, which seriously affects product quality and performance. Generally speaking, different series of aluminium alloys have different characteristics when faced with welding. 7 series aluminium alloys, as aerospace aluminium sheets, cannot be used for welding. Next, we will introduce the welding difficulties of 7 series aluminium alloy materials.

(1) Series 7 aluminium alloys are extremely susceptible to oxidation. In the air, aluminium is easily combined with oxidation to produce a dense aluminium trioxide film (thickness about 0.1-0.2μm) with a high melting point (about 2050°C), far exceeding the melting point of aluminium and aluminium alloys for sale (about 600°C). The density of alumina is 3.95-4.10g/cm3, which is about 1.4 times that of aluminium. The surface of alumina film is easy to absorb moisture, and when welding, it hinders the fusion of the base metal, which is very easy to form defects such as porosity, slag, and unfused, causing the performance of the weld to decline.

(2) 7 series aluminium alloy is easy to produce pores. The main reason for pores when welding aluminium and aluminium alloys is hydrogen, as liquid aluminium can dissolve a large amount of hydrogen, while solid aluminium hardly dissolves hydrogen, so when the temperature of the molten pool is rapidly cooling and solidifying, hydrogen can't escape in time, and it is easy to gather in the weld to form pores. Hydrogen porosity is difficult to avoid completely at present, and there are many sources of hydrogen, such as hydrogen in the arc welding atmosphere, 7 series aluminium alloy, and moisture in the air adsorbed on the surface of the welding wire. Practice has proved that even if argon gas according to GB/T4842 standard requirements, the purity of 99.99% or more, but when the moisture content reaches 20ppm, there will be a large number of dense pores, when the relative humidity of the air exceeds 80%, the weld will be obvious pores.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog