First of all, let's take a look together, in the aluminum plate for sale shearing process, we should pay attention to the following points:.

One: scratch phenomenon: scratch phenomenon is a relatively common phenomenon in the shear aluminum plate, in the process of advancing the shear will be friction with the shear feed port, there are scratches, affecting the quality of the surface appearance, if the quality of the plate surface requirements of users recommended after the lamination (surface lamination, aluminum plate surface protection) in the shear process.

Two: accurate size: length, width to be accurate and reasonable, diagonal tolerance control between 1-2mm, of course, for small specifications of shear can not control so precise.

Three: cutting edge neat: part of the shearing machine shear knife due to not sharp, and lead to aluminum cutting edge edge is not neat, it is recommended to look for large processing enterprises as well as new-style processing equipment in processing.

The above points are prone to shear process for the problem, of which the size of accurate for the most important.

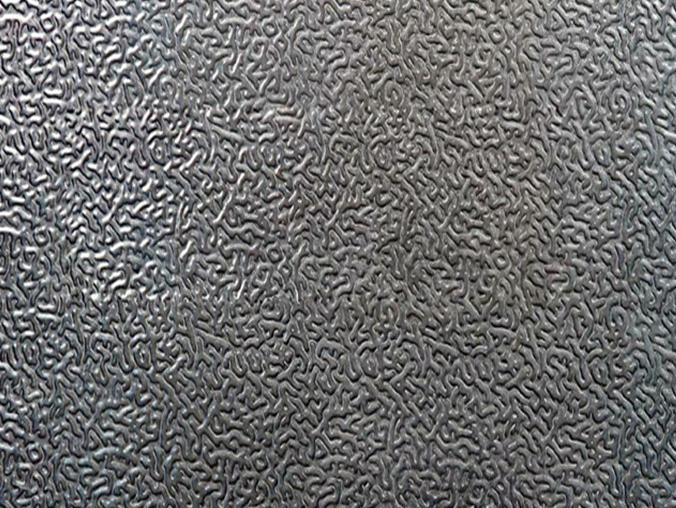

Next we look at the chemical polishing of aluminium for sale after the fog and small pits is what is going on? Chemical polishing after the fog is caused by recrystallisation, the surface coarse crystal layer is small and foggy. From the extrusion process and homogeneous process to improve. The general condition of small pits is caused by slag and porosity, which can be improved from the melt quality.

Generally the following three situations.

The first situation: aluminium has trapped slag material and air bubbles

The second condition: is alkali pickling when the time is too long corrosion time caused by fogging

The third situation: if the aluminium plate has no quality problems, it belongs to the corrosion of excessive. The original aluminium plate has a small slag, generally in 20-60um, into a flaky distribution. It will shadow the chemical polishing after fogging, aluminium plate in the casting without hydrogen removal, hydrogen content is very large, will start a small pit. Slag and gas will generally be concentrated in the aluminum plate, there will be slag and gas, there will be slag. Many aluminium sheet manufacturers do not pay attention to these, resulting in these defects. If you don't believe me, you can do metallographic and SED scanning electron microscope analysis.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog