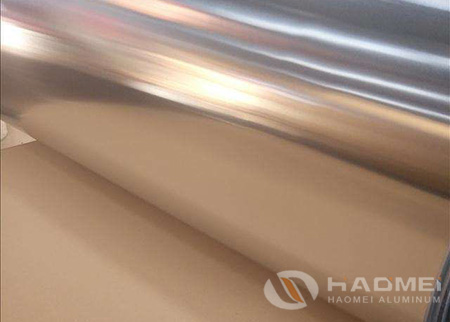

Uneven colouring of aluminium sheets

First of all, we should understand how the uneven colouring of the aluminium sheet oxidation occurs. The surface of aluminium alloy sheets has a layer of oxide film, which not only has an aesthetic effect, but also protects the aluminium alloy coil from external aggressions. However, there are times when the colour of the oxide film can be uneven. So what is the reason for this situation to occur?

1, the work area is too large, the operation is too large swing in the slot, with the edge and the centre of the touch of the solution, update the exchange has a big difference, and then in the oxide film generated by the colour inconsistency. Preventive measures: oxidation workpiece rotary undulation is small, can be quiet disposal, but when the solution temperature is too low prone to map-like spots, appear unnatural.

2, alloy aluminum coil processing cladding layer is damaged part is cut off, outside wearing high quality aluminum alloy, the inner layer is miscellaneous aluminum, because the difference is large, so after oxidation will produce "vitiligo" like spots.

3、Problems of process operation: the workpiece alkaline etching disposal is incomplete, the original part of the oxide film, dirt can not be removed; alkaline etching light immediately after disposal, the surface is still alkaline; in the process of transferring the workpiece contact foreign objects.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog