The production process of aluminium sheets and coils

Aluminium coils and aluminium sheets are increasingly used in various industries, do you know the production process of aluminium sheets? Haomei Aluminium gives you a brief introduction to it.

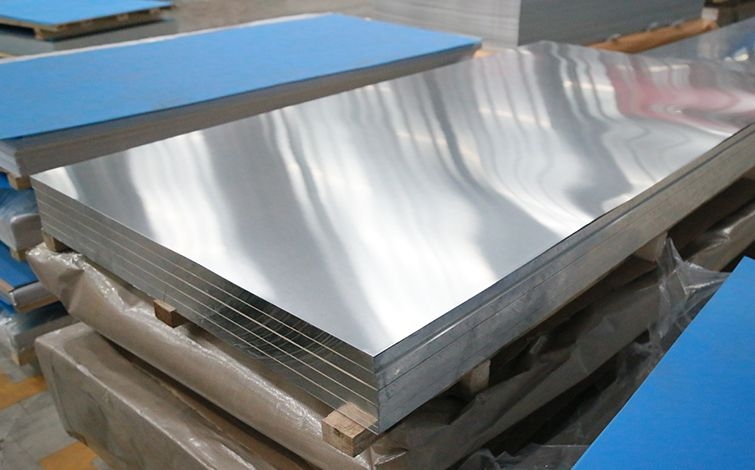

1. Aluminium and aluminium alloy sheet and strip are supplied in hot-rolled state, annealed state, various levels of soft state and various heat treatment states.

2. Aluminum plate or aluminum coil in hot rolling before the preparation mainly includes ingot quality inspection, even heat, sawing, milling, aluminum cladding and heating, etc..

3. Semi-continuous casting when the cooling rate is very high, the diffusion process in the solid phase is difficult, the ingot internal formation of chemical composition and organization is easy to uneven, such as intracrystalline segregation, etc., so that plasticity is reduced

4. If the ingot surface has defects such as deviated floaters, slag, scars and cracks, milling should be carried out (see milling of non-ferrous metal alloy ingot billets), which is an important factor to ensure good surface quality of the finished product

5. Hot rolling: aluminum alloy ingot hot rolling is to provide billets for cold rolling, or direct production of hot-rolled state of the thick plate.

6. Hot rolling process system, including the rate of press down, rolling temperature, rolling speed and lubrication and cooling.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog