The use of aluminium alloys for automobiles in the world

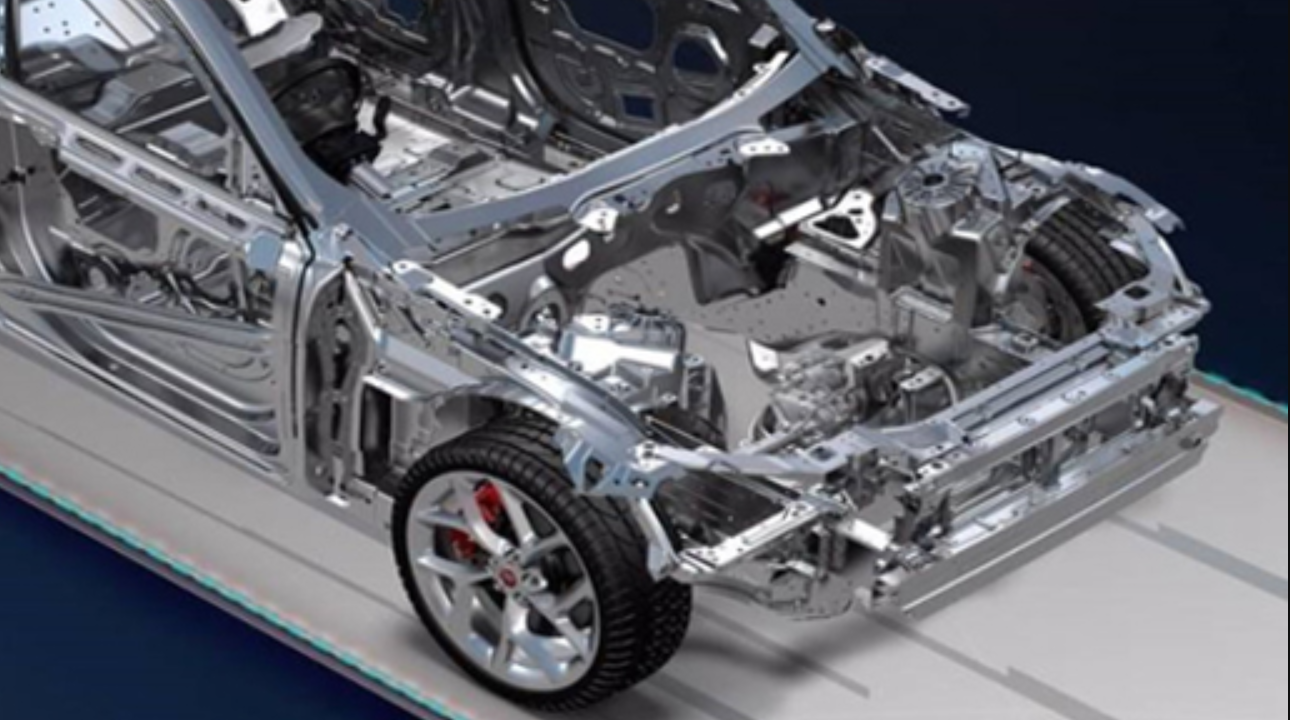

At present, the United States, Japan and Germany are the countries that use the most aluminium alloys in their cars, such as the Volkswagen AudiA8 and A2 in Germany and the NXS in Japan, which use up to 80% of aluminium alloys in their bodies. Some information shows that replacing the traditional steel structure with aluminium alloy structure can reduce the mass of the car by 30% to 40%, the manufacturing engine by 30% and the wheels by 50%. The use of aluminium alloy is one of the important ways to lighten the weight of automobiles and to improve environmental protection, energy saving, speed and transportation efficiency. Therefore, the research and development of aluminium alloy cars is now very necessary. The main advantages of aluminium alloys are their light weight and good heat dissipation. With the development of engine technology, the valve structure has become the mainstream design trend for engines.

Compared with two-valve engines, four-valve cylinder head per cylinder than two-valve cylinder head per cylinder in the work to generate more heat, the use of all-aluminium alloy cylinder head is the best solution. At present, the car engine components in not only the piston, radiator, oil pan cylinder block using aluminium alloy material, and cylinder head, crankcase also use this material. In the current form, the use of aluminium alloy on the engine instead of cast iron has become the mainstream trend. French cars already have 100% aluminium cylinder liners and 45% aluminium cylinder blocks. In the coming years, with the successful development of high strength and high quality aluminium alloy materials and the continuous improvement of the manufacturing process, aluminium alloy materials will be more and more used to manufacture this kind of parts. Aluminium alloys for automobiles can be divided into cast aluminium alloys and deformed aluminium alloys. Cast aluminium alloys are the most used in automobiles, accounting for more than 80%, which are divided into gravity casting parts, low pressure casting parts and other special casting parts. Deformed aluminium alloys include plates, foils, extrusions, forgings and so on. Although there are some differences in the composition of aluminium alloy materials for industrial use in various countries in the world, they are generally the same. The composition of its varieties: castings account for about 80%, forgings account for 1% to 3%, and the rest are processing materials. In the United States, deformed aluminium alloys account for a large proportion of the automobile industry, reaching 36%.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog