Aluminum-lithium alloy has low density, high specific strength and specific stiffness, replacing conventional high-strength aluminum alloy can reduce the mass of components by 10%~20%, and increase stiffness by 15%~20%.

Medium strength weldable aluminum-lithium alloy 1420 is a low-density, medium-strength, corrosion-resistant and weldable aerospace structural parts. It is mainly used in the production of various structural parts such as medium and thick plates, thin plates, profile bars and forgings. There is also 2091 medium strength aluminum-lithium alloy, which has good low-temperature toughness and stress corrosion resistance, and is mainly used in the shell of high-speed aircraft, cryogenic containers and fighter rear compartments. High-strength aluminum-lithium alloy is mainly based on copper as the main strengthening element of 2000 series aluminum-lithium alloy, which not only has the advantages of high strength, high modulus, weldability and low specific gravity, but also significantly better than the 7000 series ordinary aluminum alloy with zinc as the main strengthening element in terms of heat resistance and corrosion resistance. It is mainly used for space shuttle ultra-light storage tanks, parts bearing high loads inside the fuselage, rocket combustion and liquid oxygen containers, etc., while medium and high strength aluminum lithium alloys replace 2XXX and 7XXX alloys in the aerospace industry.

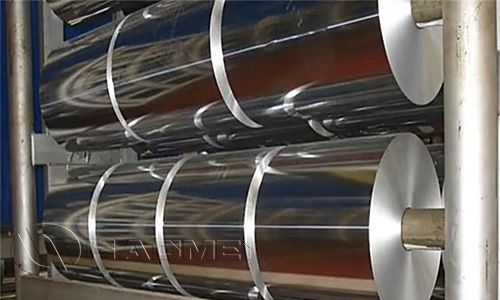

Next we look at the production of aluminum-lithium alloys. Because the melting point of lithium is low, and it is much lighter than aluminum, which brings difficulties to adding lithium in the melting alloy process, if the protection is not good when adding lithium, the lithium floats to the liquid surface and burns, which will cause the burning of the alloy, making the composition of lithium in the alloy more difficult to control. Because the specific gravity of lithium is very small, adding aluminum is easy to cause component segregation, increasing the difficulty of firing alloys. Aluminum-lithium alloy is prone to alloy oxidation during casting, and destructive explosion accidents are also prone to occur, so the melting and casting of aluminum-lithium alloy can not use traditional aluminum alloy production technology and equipment. The uncrystalline grain structure of aluminum-lithium alloy is also called layered structure, and the principle of strengthening toughness is to use the flat unrecrystallized grain structure to reduce the harm of cracking along the crystal and obtain a special toughening mechanism. The main disadvantage of lamellar tissue is the low transverse-short performance.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog