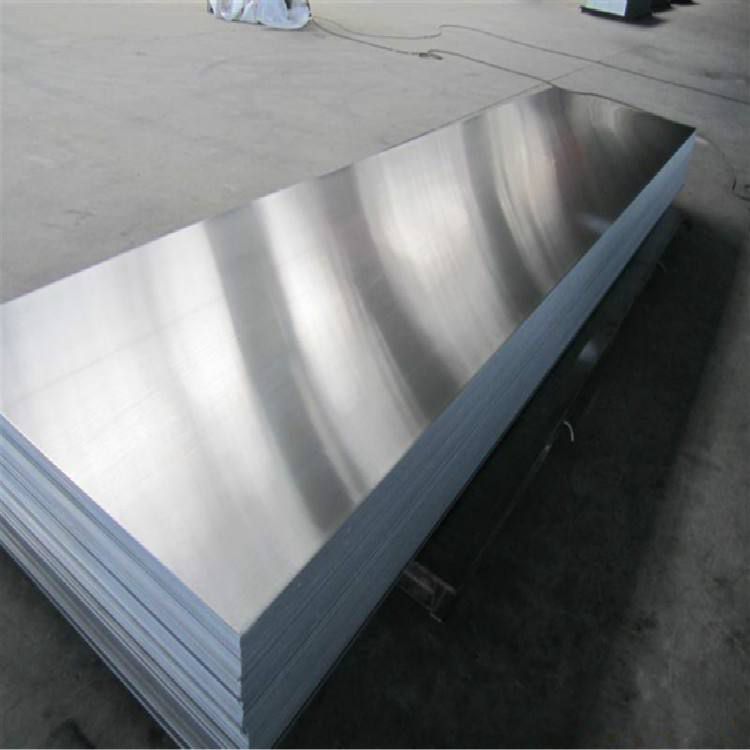

The production process of aluminium alloys

As society progresses, aluminium alloys are becoming more and more versatile. But do you know the production process of aluminium alloys? Today, Hormel Aluminium gives you a brief introduction to the quenching of aluminium alloys in the production process.

The most commonly used quenching medium for aluminium alloy quenching furnace is water. Because of the small viscosity of water, large heat capacity, fast evaporation of heat, strong cooling capacity, and very convenient and economic to use. But it has the disadvantage of reduced cooling capacity after heating. The quenching and heating of products cooled in water can be divided into three stages: the first stage is the film boiling stage. When the incandescent products and cold water just contact, in its surface immediately formed a layer of uneven superheated steam film, it is very firm, poor thermal conductivity, so that the cooling rate of the products reduced. The second stage is the bubble boiling stage. When the vapour film is destroyed, the liquid near the surface of the metal produces violent boiling and strong heat exchange occurs. The third stage is the heat convection stage, the circulation of cooling water, or products swinging from side to side, or moving up and down, increasing the surface of the product and the water to produce convection heat exchange to increase the cooling rate.

According to the above analysis, in order to quickly break through the first stage, bursting into a cooling step to ensure uniform cooling of quenched products, the need to quench the water tank is equipped with compressed air pipe, in order to stir, while the product into the water tank to make the appropriate swing. In addition to ensure that the water temperature does not rise too much, the quenching tank should have sufficient capacity (generally should be quenched products more than 20 times the total volume). And cooling water should be circulating device.

In addition to adjusting the water temperature to control the quenching and cooling rate of the aluminium quenching furnace, you can also add different solvents to the cooling water to adjust the cooling capacity of the water. Usually use polyethanol aqueous solution as a cooling medium, but also can adjust the concentration of polyethanol aqueous solution to control the cooling rate of the product quenching. Generally easy to deform the products, often with this polyethanol aqueous solution to quench.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog