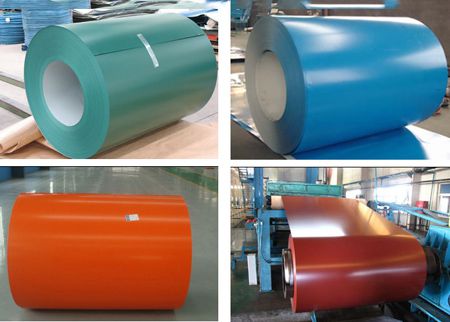

Color coated aluminum coil is widely used in the construction industry for its attractive appearance and durability. The producing process of color coated aluminum coil involves several steps that are critical to ensuring a high-quality final product.

The first step in the producing process of color coated aluminum coil is cleaning and preparing the surface. The aluminum coil is first cleaned to remove any impurities or contaminants from the surface. This is typically done using a combination of mechanical and chemical methods. Any residual oil, grease, or other contaminants must be removed to ensure that the surface is clean and free of debris.

Once the surface has been thoroughly cleaned, the aluminum coil is treated with chemicals to enhance its adhesion properties, improve corrosion resistance, and increase durability. This step is critical to ensuring that the color coating will adhere properly to the surface of the aluminum coil and will not peel or flake off over time.

After the chemical treatment is complete, a primer coating is applied to the surface of the aluminum coil. The primer coating provides a base for the color coating and improves the adhesion of the color coating to the aluminum surface. The primer coating is typically applied using a spray or roller coating process.

Once the primer coating has been applied and allowed to dry, the color coating is applied to the surface of the aluminum coil. The color coating is typically applied using a special roller coating process. The color coating is available in a variety of colors, and the thickness and quality of the coating can be customized to meet specific requirements.

After the color coating has been applied, the color coated aluminum coil is cured in an oven at a specific temperature and for a specific duration to ensure that the coating is fully cured. This step is critical to ensuring that the color coating is durable and long-lasting.

Once the curing process is complete, the color coated aluminum coil is inspected for quality and packaged for shipment. The final product must meet strict quality standards to ensure that it performs as expected in the field.

In conclusion, the producing process of color coated aluminum coil is a complex and multi-step process that requires careful attention to detail and a commitment to quality. By following these steps, manufacturers can produce high-quality color coated aluminum coil that is durable, long-lasting, and attractive.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog