Overview of anodised aluminium sheets and their advantages

Anodic oxidation is the electrochemical oxidation of a metal or alloy, in which aluminium and its alloys are subjected to a process of forming an oxide film on aluminium products (anodes) under the action of an applied current in the corresponding electrolyte and under specific process conditions. Anodising not only solves the defects of aluminium surface hardness and wear resistance, but also prolongs the service life and enhances the aesthetics of aluminium, and has become an indispensable part of aluminium surface treatment.

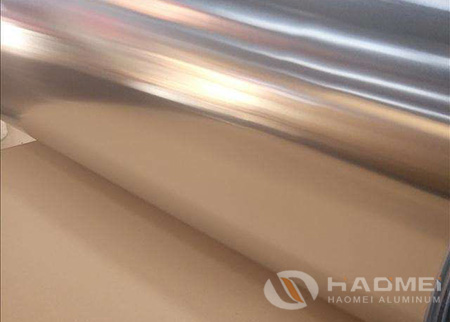

The anodic oxidation of aluminium sheets is carried out by placing them in the corresponding electrolyte (e.g. sulphuric acid, chromic acid, oxalic acid, etc.) as an anode, under specific conditions and with an applied current. The anodised aluminium sheet is oxidised and a thin layer of aluminium oxide is formed on the surface, with a thickness of 5 to 20 microns, and hard anodised films of up to 60 to 200 microns. The anodised aluminium sheet improves its hardness and wear resistance up to 250~500 kg/mm2, good heat resistance , the melting point of the hard anodised film is up to 2320K, excellent insulation, breakdown voltage resistance up to 2000V, enhanced corrosion resistance, no corrosion after several thousand hours in ω=0.03 NaCl salt spray. The thin layer of oxide film has a large number of microporous, can adsorb various lubricants, suitable for the manufacture of engine cylinders or other wear-resistant parts; film microporous adsorption capacity can be coloured into a variety of beautiful and bright colours. Non-ferrous metals or their alloys (such as aluminium, magnesium and their alloys, etc.) can be anodised.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog