When it comes to choosing between magnesium and aluminum alloy for making a vehicle, there are several factors that need to be considered. Both materials have their own advantages and disadvantages.

Magnesium is a lightweight metal that has a density of 1.74 g/cm3, making it the lightest structural metal. It is 33% lighter than aluminum and 75% lighter than steel. Magnesium is also a very strong material, with a tensile strength of 420 MPa.

However, magnesium is also a very reactive metal and can corrode easily, especially when exposed to salt or moisture. It is also more expensive than aluminum and can be difficult to work with.

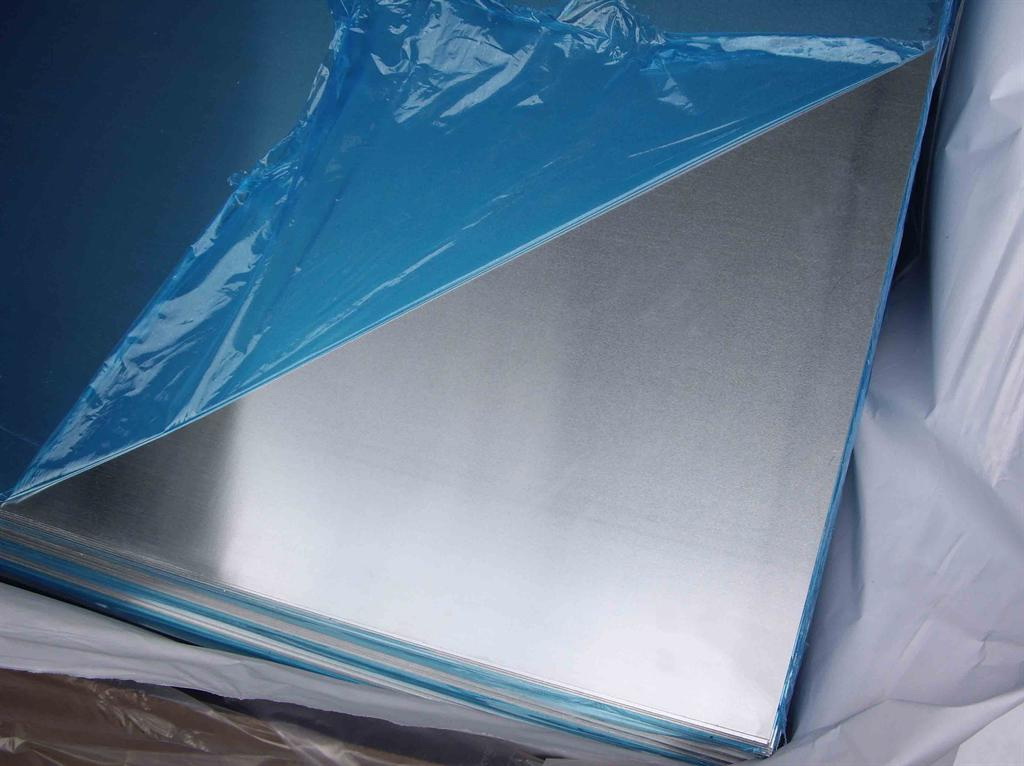

Aluminum alloy is a popular choice for making vehicle parts due to its strength and durability. It is also lightweight, with a density of 2.7 g/cm3. Aluminum alloy is also resistant to corrosion and has a high strength-to-weight ratio.

However, aluminum alloy is not as strong as magnesium and has a lower tensile strength of 310 MPa. It also requires more energy to produce than magnesium, which can make it more expensive in some cases.

In conclusion, both magnesium and aluminum alloy have their own advantages and disadvantages when it comes to making a vehicle. Magnesium is lighter and stronger, but also more expensive and prone to corrosion. Aluminum alloy is also lightweight and durable, but not as strong as magnesium and may require more energy to produce. Ultimately, the choice between these two materials will depend on the specific needs and requirements of the vehicle being produced.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog