As a new aluminum sheet dealer, it is important to ensure that the aluminum sheets you are selling are of high quality and meet the specifications required by your customers. There are several methods that can be used to test the quality of aluminum sheets before selling them to customers. These methods ensure that the aluminum sheet is free from any defects, impurities or cracks, and has the required strength and thickness.

The following are some of the methods that can be used to test the quality of aluminum sheets:

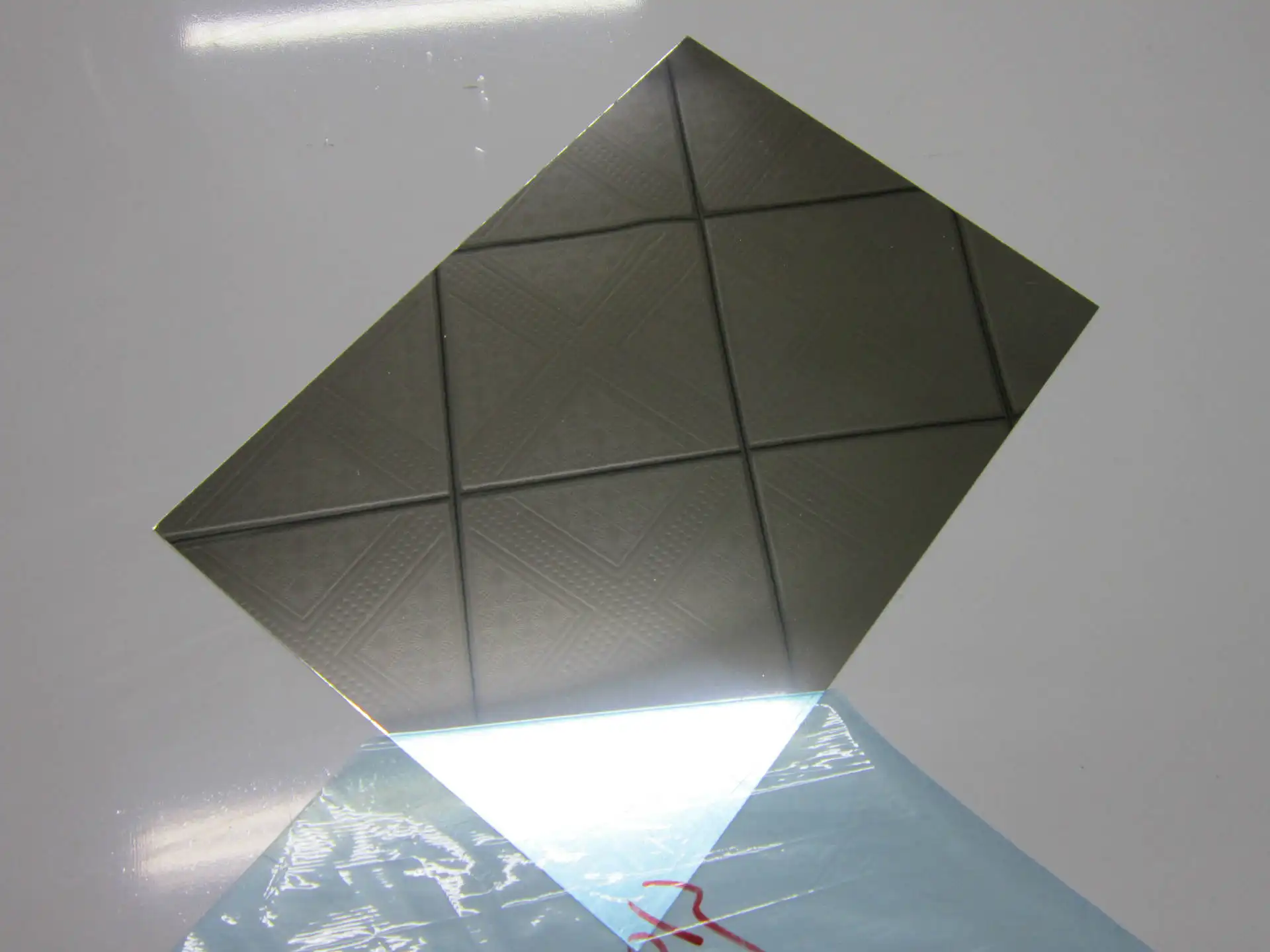

Visual Inspection: The first step is to visually inspect the aluminum sheet for any defects, such as scratches, dents, or cracks. This can be done by looking at the sheet from different angles and under different lighting conditions. Visual inspection is a quick and easy way to identify any visible defects on the sheet.

Measurement of Thickness: The thickness of the aluminum sheet can be measured using a micrometer. This will help to determine if the sheet is of the correct thickness as specified by the manufacturer. The thickness of the aluminum sheet is an important factor that determines its strength and durability. It is important to ensure that the thickness of the sheet meets the required specification.

Chemical Composition Analysis: Another way to test the quality of aluminum sheets is by conducting a chemical composition analysis. This can be done by using an X-ray fluorescence (XRF) analyzer, which will determine the composition of the material and identify any impurities. Chemical composition analysis is an important method to identify any impurities in the sheet that can affect its quality and durability.

Tensile Testing: Tensile testing is a common method used to test the strength of aluminum sheets. This involves stretching the sheet until it breaks and measuring the force required to do so. This test can be done using a tensile testing machine. Tensile testing is an important method to determine the strength and durability of the sheet.

Bend Testing: Bend testing is another method used to test the strength of aluminum sheets. This involves bending the sheet to a certain degree and checking for any cracks or defects. This test can be done using a bending machine. Bend testing is important to identify any defects or cracks in the sheet that can affect its strength and durability.

By using these methods, a new aluminum sheet dealer can ensure that the sheets they are selling are of high quality and meet the specifications required by their customers. Using these methods will also help to maintain the reputation of the dealer and ensure customer satisfaction.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog