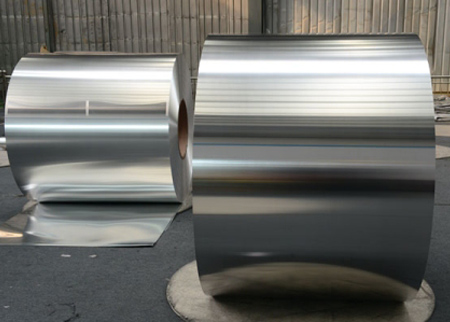

When the aluminum foil is heat-sealed to make Haomei heat seal foil for sale, the plastic film becomes a viscous fluid state when the heat sealing temperature is above the heat sealing temperature; while the heat sealing pressure makes the interface molecules of the viscous fluid state generate an external power of mutual penetration and diffusion between the interface molecules of the plastic film in a viscous fluid state; The sealing time will make the interface molecules of the plastic film penetrate and diffuse into each other as soon as possible, so that the interface disappears and the aluminum foil and plastic film becomes a whole, because it has good sealing performance. And today we are going to explain the heat sealing process of Haomei heat seal foils in detail.

The lower heat-sealing temperature of the heat seal aluminum material depends on the melting temperature of the material. The heat-sealing temperature should be higher than the melting temperature of the heat-sealing material, but by how much, it should be considered whether the material to be sealed is a single film or a composite film, and the thickness of the film. Technical indicators such as sealing pressure and heat sealing speed. Generally, if the heat sealing pressure is high, the heat sealing speed is slower; and if the aluminum foil film thickness is greater, the heat sealing temperature can be lower, and vice versa.

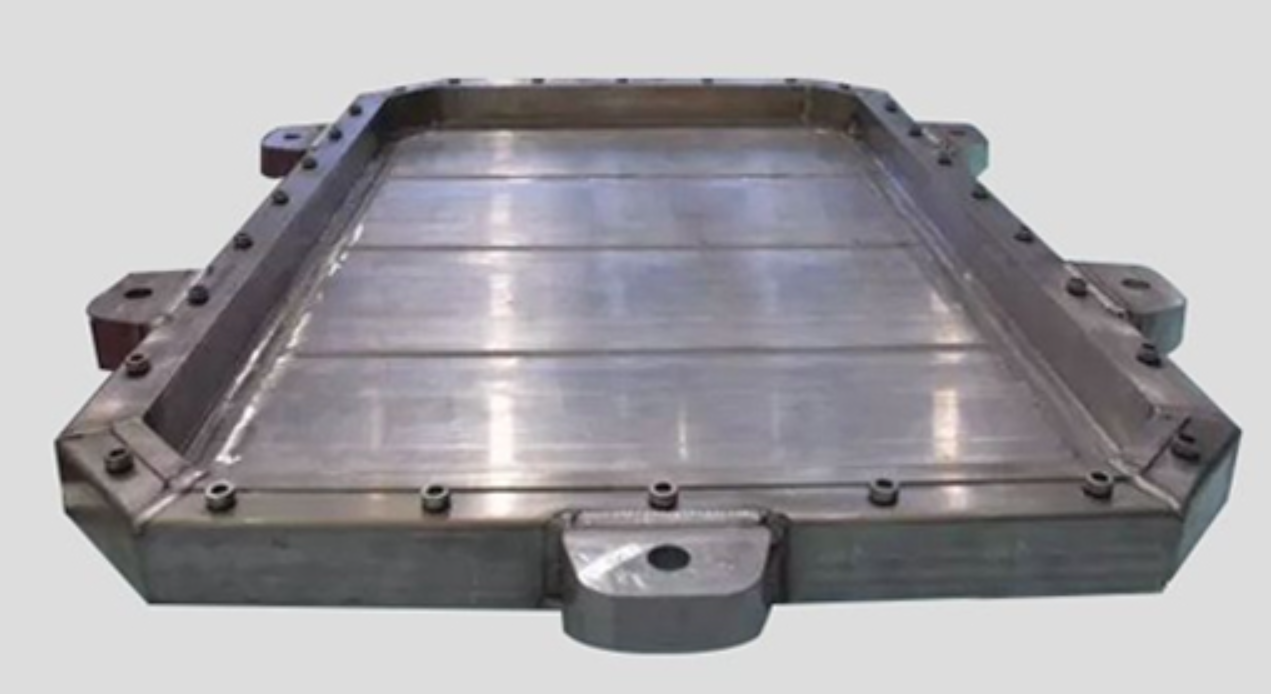

The size of the heat sealing pressure also has a great influence on the heat sealing effect of the heat seal foil, and even cause local leakage. When the heat sealing pressure is too great, and when the heat sealing temperature is slightly higher, the heat sealing knife will easily squeeze the melt in the sealing seam during heat sealing of aluminum foil, resulting in the phenomenon of "hot cutting". Lightly reduce the heat sealing strength of the seal, so that the impact strength of the seal decreases.

Under the same heat-sealing temperature and heat-sealing pressure, the longer the heat-sealing time is, the stronger the interface of the heat seal foil's layer is. At the same time, if the heat sealing time is too long, it is easy to cause wrinkling and deformation of the sealing seam of the aluminum foil package, affecting the appearance and causing leakage of the package.

Haomei is a professional aluminum foil wholesaler and we are currently promoting a large amount of in-stock aluminum foils for packaging and heat seal foil for sale. If you want to buy them, please contact us at E-mail: sale@alusuppliers.com.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog