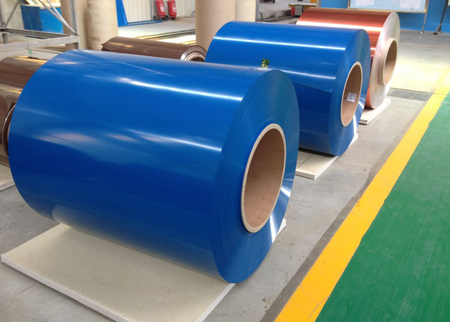

When it comes to making capacitors, conductive aluminum foil is the preferred choice due to its unique properties. Capacitors are electronic components that can store electric charge, and they are used in a wide range of applications, from power supplies to audio equipment to computers.

Normal aluminum foil, on the other hand, is not suitable for making capacitors. It has lower electrical conductivity, making it less effective at transferring electrical energy, and it is also thicker and less flexible than conductive aluminum foil, which makes it harder to work with and limits its use in the construction of capacitors.

The main difference between normal aluminum foil and conductive aluminum foil is their electrical conductivity. Conductive aluminum foil has a much higher conductivity than normal aluminum foil. This means that it can more effectively transfer electrical energy, making it ideal for use in capacitors. This higher conductivity also allows for the construction of capacitors with higher capacitance values, which is important for many applications.

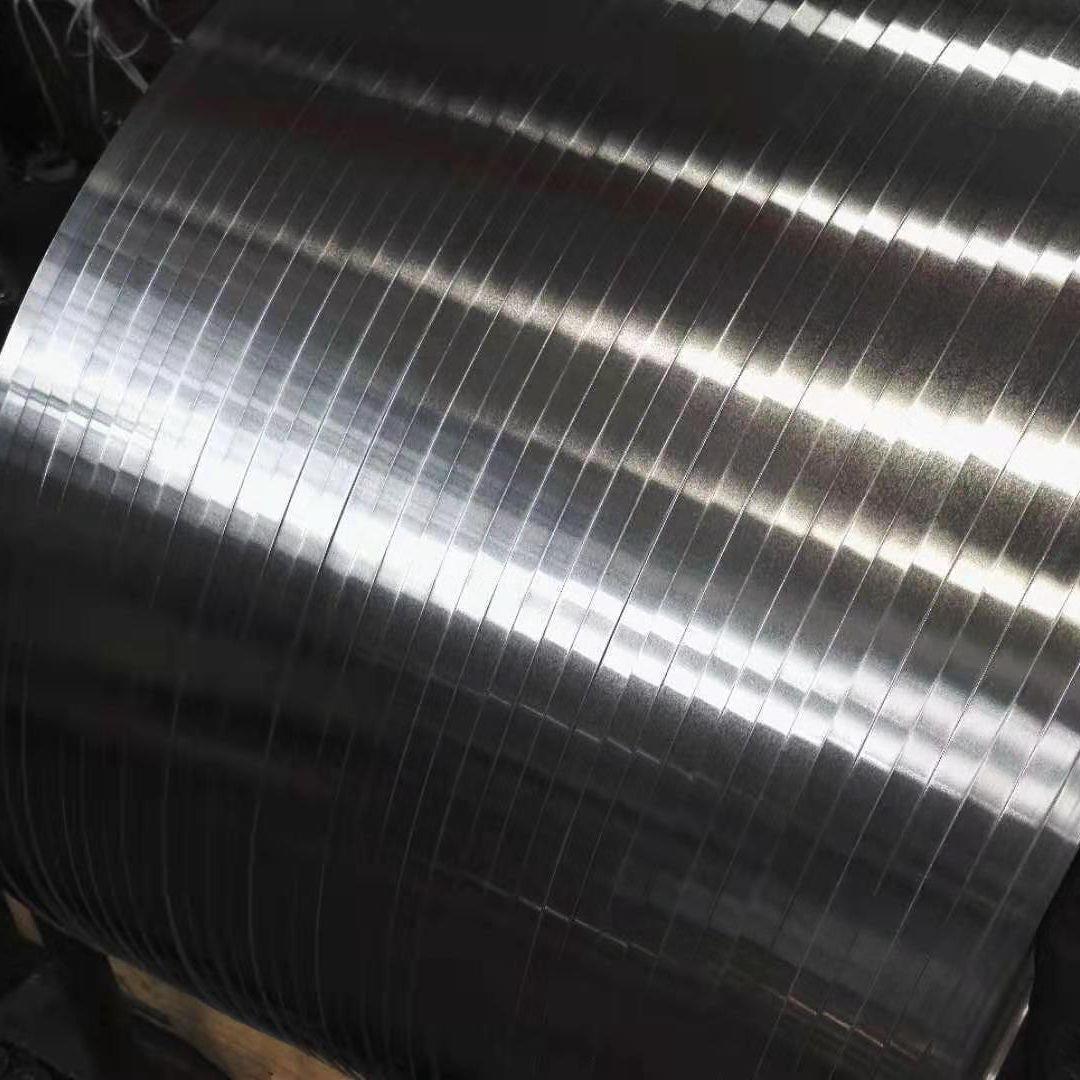

In addition to its high conductivity, conductive aluminum foil is also thinner and more flexible than normal aluminum foil. This makes it easier to work with and allows for more precise construction of capacitors. The thinness of conductive aluminum foil also means that it can be used to create capacitors with smaller physical dimensions, which is important in applications where space is limited.

Another key difference is that conductive aluminum foil is typically coated with a thin layer of oxide to enhance its electrical properties. This oxide layer helps to increase the surface area of the foil, which in turn improves its capacitance. The oxide layer also helps to protect the foil from corrosion, which can be a problem when using normal aluminum foil in capacitors.

Overall, while normal aluminum foil may be suitable for some applications, conductive aluminum foil is the preferred choice for making capacitors due to its superior conductivity, flexibility, and other unique properties.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog