Are aluminium foil lunch boxes safe?

With the strengthening of the world's efforts to remedy environmental pollution caused by plastic and the growing concern about the health hazards of plasticisers in disposable plastic lunch boxes, many businesses have started to use disposable aluminium foil lunch boxes instead of plastic lunch boxes in recent years. So, is this disposable aluminium foil lunch box really safer and healthier?

Many people's awareness of aluminium foil cutlery began with airline meals. In recent years, frozen cooked food, baked cakes and other foods with a long shelf life have also started to use aluminium foil packaging.

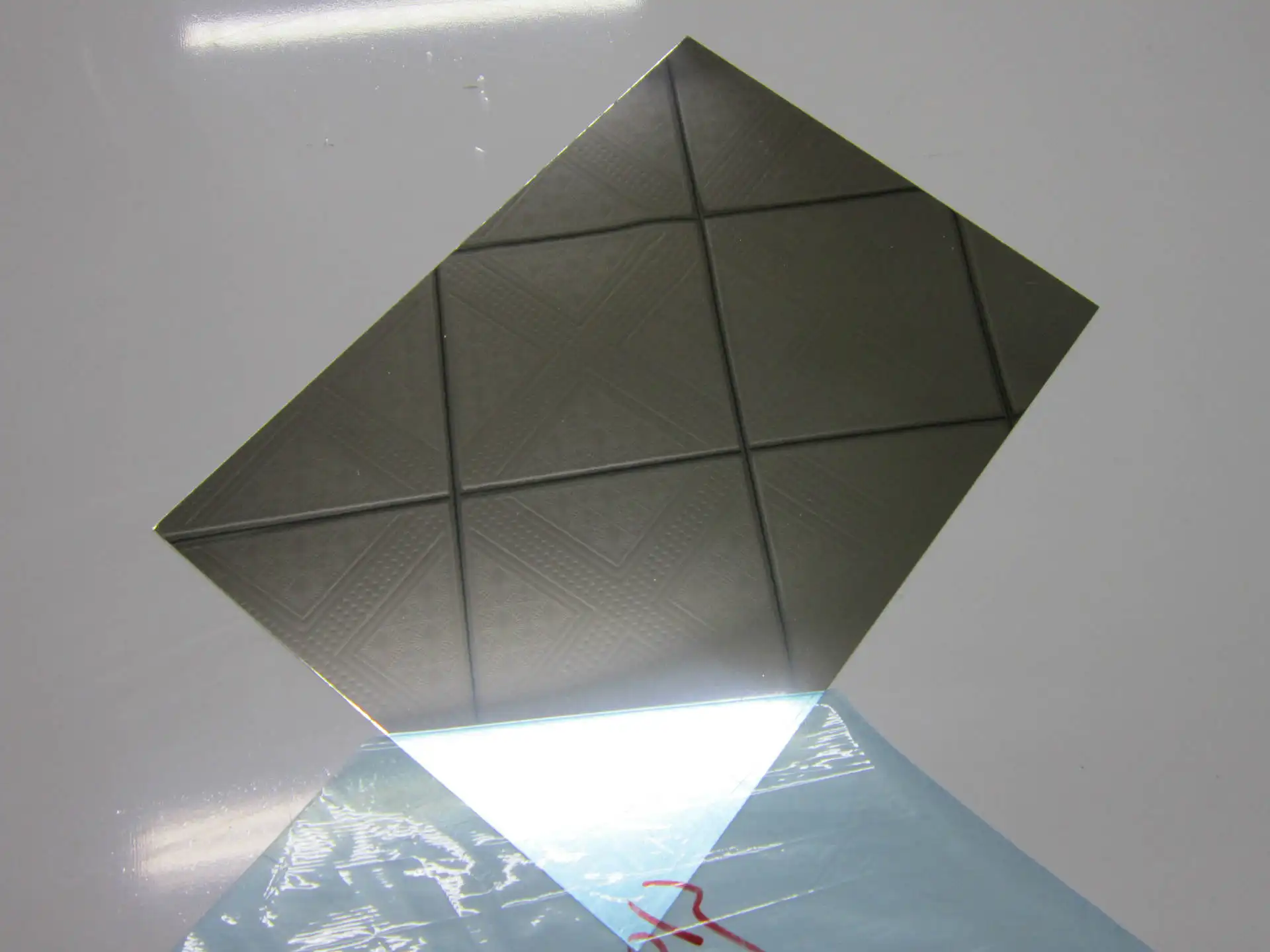

Due to its good ductility and toughness, aluminium metal can be rolled into foil thinner than normal paper. Using this excellent property, aluminium is first rolled into foil master rolls of a certain thickness and then stamped and shaped by special equipment to produce aluminium foil lunch boxes. Aluminium foil can be divided into thick foil, single-zero foil and double-zero foil according to its thickness. The thickness of thick foil is 0.1~0.2mm, the thickness of single zero foil is 0.01~0.1mm and the thickness of double zero foil is usually less than 0.01mm.

Aluminium foil lunch boxes are made of lightweight material and are easy to use. The aluminium foil lunch box is a semi-rigid container, between the thickness and hardness of the rigid aluminium cans and the flexible aluminium foil flexible tins. The thickness of aluminium cans is over 0.24mm, which is a rigid container, while the thickness of a general aluminium foil lunch box is 0.03~0.2mm. A lunch box with a volume of about 400ml weighs only a dozen grams, which is very light. The lid of an aluminium foil box is easy to open, and can be opened with a simple pull, unlike the effort required to open a food can. A wide range of applications and good thermal conductivity. Aluminium foil can be divided into plain aluminium foil, laminated aluminium foil, coated aluminium foil and many others. Plain aluminium foil is made of pure aluminium and cannot be heat-sealed packaged or heated in a microwave oven. These disadvantages can be overcome by laminating aluminium foil with organic resins and other materials, or by coating the surface of the foil with resins and other materials.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog