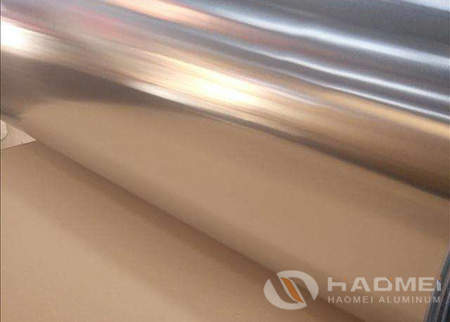

Because of its stable performance and high usage rate, container aluminum foil is very popular for sale in the market. However, white spots will appear on the container aluminum foils during production. Here's how Haomei avoids stains like white spots.

1. The viscosity of the glue liquid has a corresponding matching relationship with the number of lines of the mesh roller. If it is larger than the matching range, it will destroy the coating state of the glue, resulting in the generation of white spots and other influences.

2. Increase the particle size detection index for different batches of ink, and strictly control it, especially if the particle size and particle size distribution of the full-bottom ink type are outside the standard range, do not use it; choose a stable supplier.

3. Enterprises should adhere to the regular cleaning system of the container aluminum foil coating roller, and master the correct cleaning method of the coating roller. When producing printing film with full white background or light background color, pay attention to cleaning the scraper, coating roller, flattening roller, etc. before production.

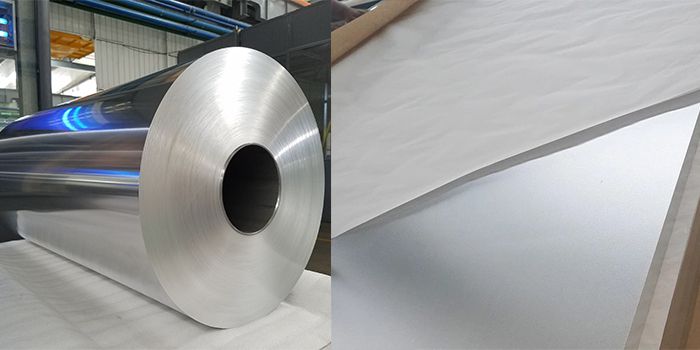

4. Aluminized film coating method is adopted. The commonly used coating process is the printing film (ink surface) gluing. Here, a special coating method is used to avoid the problem of uneven penetration of ethyl ester to the ink layer, and the coated adhesive can fully and evenly cover the container. The surface of aluminum foils is aluminized, which can eliminate white spots well. However, this process has limitations, limited to the compounding of VMPET, and other aluminized films will be stretched and deformed under the action of tension under the influence of heat in the oven; bullying will weaken the corresponding peel strength.

5. The adhesive should be completely dry. Because the barrier property of aluminum plating is better, if the bonding in the composite film is not completely dried, then the composite film of the container aluminum foil needs to be released after entering the curing chamber, and a large amount of residual solvent will be released under the barrier of the aluminum film. bubbles. There may even be no white spots when the machine is turned off, but white spots appear after curing.

6. Container aluminum foils use adhesives for aluminized films. The surface tension of the composite adhesive for aluminized film is lower, and the coating and spreading effect on the surface of the aluminized layer is obviously better. The use of aluminized glue will easily control the leveling of the glue, and have an ideal coating state. In terms of the coating state of the adhesive alone, the use of aluminized glue can eliminate the possibility of white spots.

We have large amount of in stock aluminum foils for pacakging for sale right now at low price. If you are interested, please contact us!

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog