Coating of aluminium foil

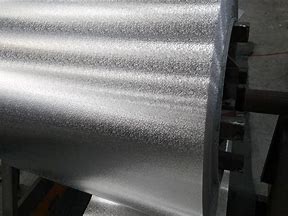

The board type is an important technical indicator not only for coated aluminium foil but also for uncoated aluminium foil.

1. Coating performance.

There are many types of coated aluminium foil for heat exchangers. The coated aluminium foil currently used on the market is mainly hydrophilic, so only the coating performance indicators for hydrophilic aluminium foil are discussed here.

2. Coating thickness.

There are no hard and fast rules for the thickness of the coating on the surface of aluminium foil, which is generally below 3/1m. As coatings are generally more expensive, the thinner the coating thickness control, the lower the production cost, provided that the performance requirements are met. The thickness of the coating directly affects the performance indicators of the coating, so the coating thickness of the aluminium foil surface is required to be even and consistent.

3. Coating adhesion.

Coating adhesion is an indicator of how well the aluminium foil is bonded to its surface coating. If the coating adhesion is too small, the coated aluminium foil will easily fall off during further processing and use, which in turn will seriously affect the weight of the coated aluminium foil, so the stronger the coating adhesion, the better. The coating adhesion can only be tested qualitatively. The main testing methods are the abrasion test, the scratch test and the cupping method.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog