When it comes to making aluminum bottle caps, choosing the right type of aluminum plate is crucial. The right aluminum plate will ensure that the bottle caps are durable, corrosion-resistant, and easy to open.

1. Alloy Type

The most commonly used alloy for making bottle caps is 8011 aluminum alloy. This alloy is known for its excellent formability, high strength, and good corrosion resistance. Other alloys that can be used include 3105 and 5052.

It's important to select the proper alloy type for the intended use of the bottle cap. For instance, if the bottle cap will be used for carbonated beverages, then it's recommended to use 5052 alloy. This is because 5052 alloy has better resistance to pressure and deformation.

2. Thickness

The thickness of the aluminum plate will depend on the size and shape of the bottle cap. In general, the thickness of the plate should be between 0.18mm and 0.23mm.

It's essential to choose the right thickness, as it will affect the cap's strength and durability. If the aluminum plate is too thin, the bottle cap may deform easily, and if it's too thick, it may be challenging to remove.

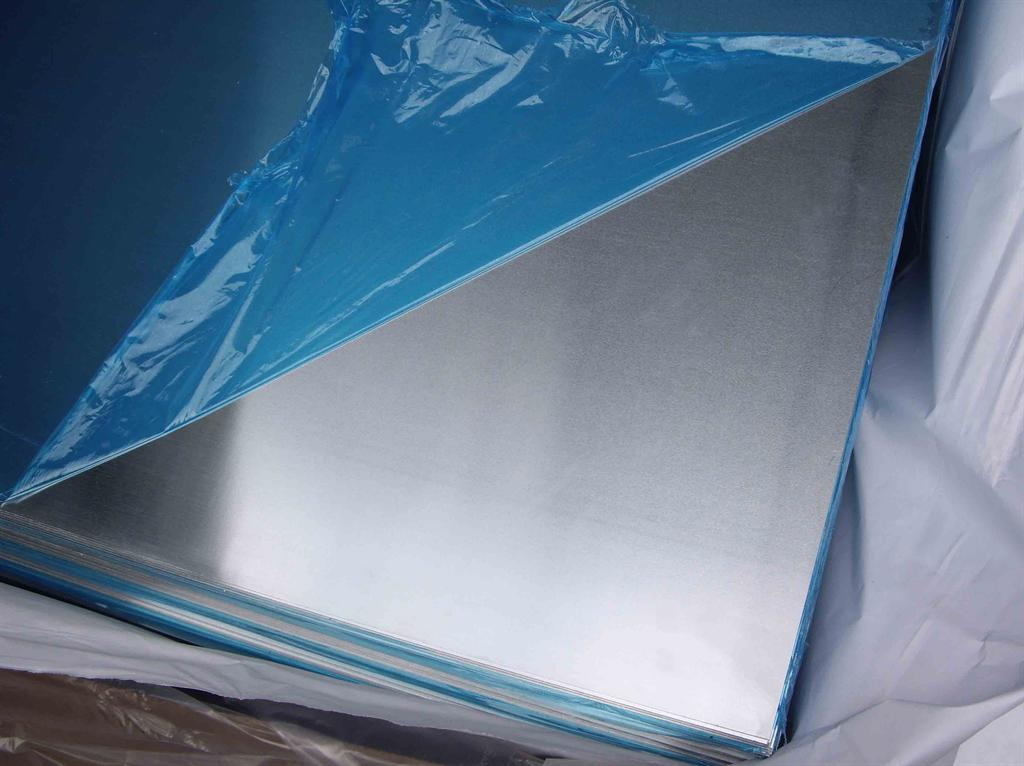

3. Surface Treatment

The surface of the aluminum plate should be treated to improve its corrosion resistance and adhesion properties. One common method is to apply a coating of lacquer, which can be either clear or colored.

The coating of lacquer also enhances the appearance of the bottle cap and protects it from external elements. It's essential to note that the lacquer coating should be food-grade, as it will come into contact with the liquid inside the bottle.

4. Temper

The temper of the aluminum plate will affect its strength and formability. The most commonly used temper for bottle caps is H14, which provides a good balance of strength and formability.

It's crucial to determine the appropriate temper for the intended use of the bottle cap. For instance, if the bottle cap will be used for hot-fill applications, then it's recommended to use T4 temper. This is because T4 temper provides better resistance to thermal stress.

Conclusion

Choosing the right type of aluminum plate is essential for making high-quality bottle caps. By considering factors such as alloy type, thickness, surface treatment, and temper, you can ensure that your bottle caps are durable, corrosion-resistant, and easy to open.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog